Electronic and electromechanical components are often exposed to environments that contain moisture, chemicals, salts, oils, and airborne contaminants. These stressors can degrade materials, weaken protective finishes, increase electrical resistance, or allow corrosion to propagate inside sensitive assemblies. For products used in aerospace, defense, medical, industrial, and outdoor equipment, understanding how materials respond to these exposures is essential to long term field performance.

Grayhill conducts corrosion testing, chemical resistance testing, and seal integrity testing to ensure that products withstand the environments they will face throughout their service life. These tests help evaluate failure risks and support more robust engineering decisions during design and qualification.

Why Environmental Exposure Matters for Reliability

Environmental exposure can affect materials and assemblies in several ways:

- Metal corrosion caused by salt, humidity, or chemical exposure

• Degradation of coatings, platings, and surface finishes

• Swelling or weakening of plastics or elastomers

• Seal failure that allows moisture or chemicals to enter enclosures

• Increased contact resistance in electromechanical interfaces

• Mechanical weakening of fasteners or structural hardware

Extensive research by NACE International, SAE, ASTM International, and materials engineering laboratories has shown that corrosion and chemical attack are leading contributors to long term electronic degradation in fielded systems.

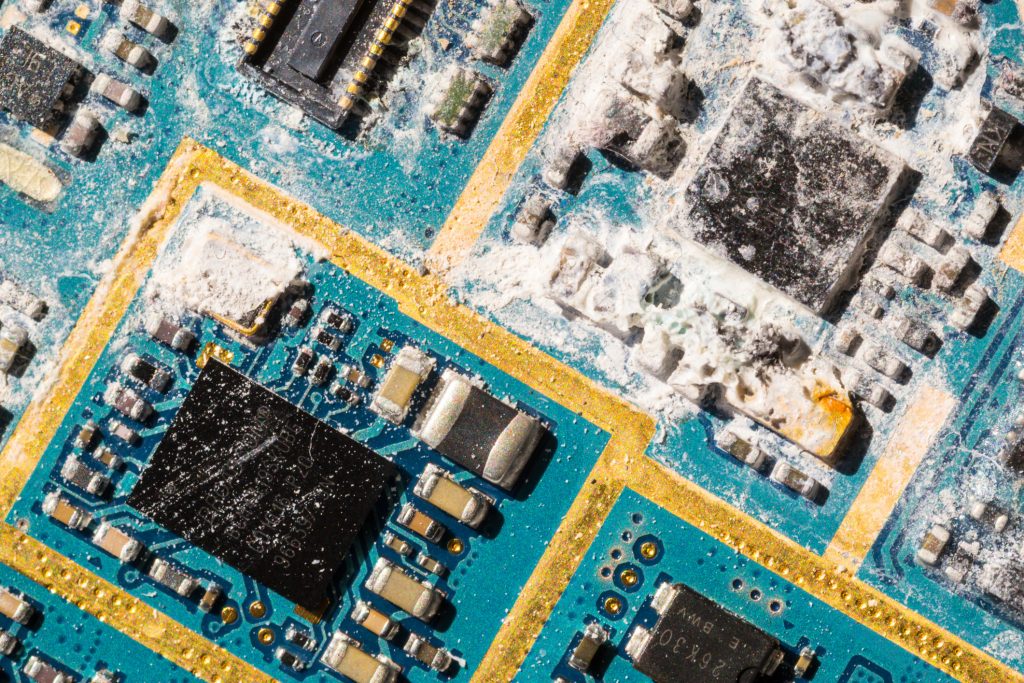

Corrosion does not need to be visible to be harmful. Even small amounts of oxidation inside connectors, PCBs, or contact surfaces can affect performance. Seal degradation is equally critical, as moisture or fine particles can migrate into areas protected during initial assembly but exposed during long term use.

Salt Spray Testing

Salt spray (or salt fog) testing is one of the most widely used methods for evaluating corrosion resistance of coatings, metals, and assemblies. It is defined in ASTM B117, a standard originally developed in 1939 and still used today across aerospace, defense, automotive, and industrial manufacturing.

Salt spray testing exposes components to a controlled fine mist of a sodium chloride solution at an elevated temperature, typically 35 degrees Celsius. The environment accelerates corrosion formation and allows engineers to examine:

- Surface finish performance

- Plating durability

- Seal effectiveness against salt ingress

- Fastener corrosion or galling

- Material compatibility between metals and coatings

Salt spray is not a direct predictor of real-world corrosion rates. Instead, it provides a standardized way to compare material performance, identify vulnerabilities, or evaluate whether surface treatments meet expected corrosion resistance levels.

ASTM B117 is widely cited in materials science literature because its controlled environment allows consistent test comparison across suppliers, finishes, and design variants.

Chemical Resistance Testing

Many Grayhill components are used in environments where they may come in contact with fuels, lubricants, industrial solvents, hydraulic fluids, cleaning agents, or deicing chemicals. Chemical exposure can lead to:

- Softening or cracking of polymers and elastomers

- Degradation of adhesives or potting compounds

- Swelling of gaskets or O-rings

- Discoloration, loss of marking durability, or coating breakdown

- Increased friction or stiction in mechanical interfaces

Chemical resistance testing may follow several published standards depending on application needs. Relevant guidance can come from:

- ASTM D543 for chemicals affecting plastics

- ASTM D471 for elastomer swelling and degradation

- SAE AS1241 for fluid compatibility in aerospace components

- Industry specific chemical lists such as automotive fluids specified in ISO 16750-5

Grayhill evaluates the effect of chemical exposure on:

- Surface quality

- Mechanical integrity

- Tactile response of switches or rotary devices

- Contact resistance or electrical behavior

- Seal compression set or elasticity

Testing may involve immersion, splash exposure, wipe tests, or extended chemical soak. Results help confirm material compatibility and long-term performance in environments where corrosive or aggressive fluids are present.

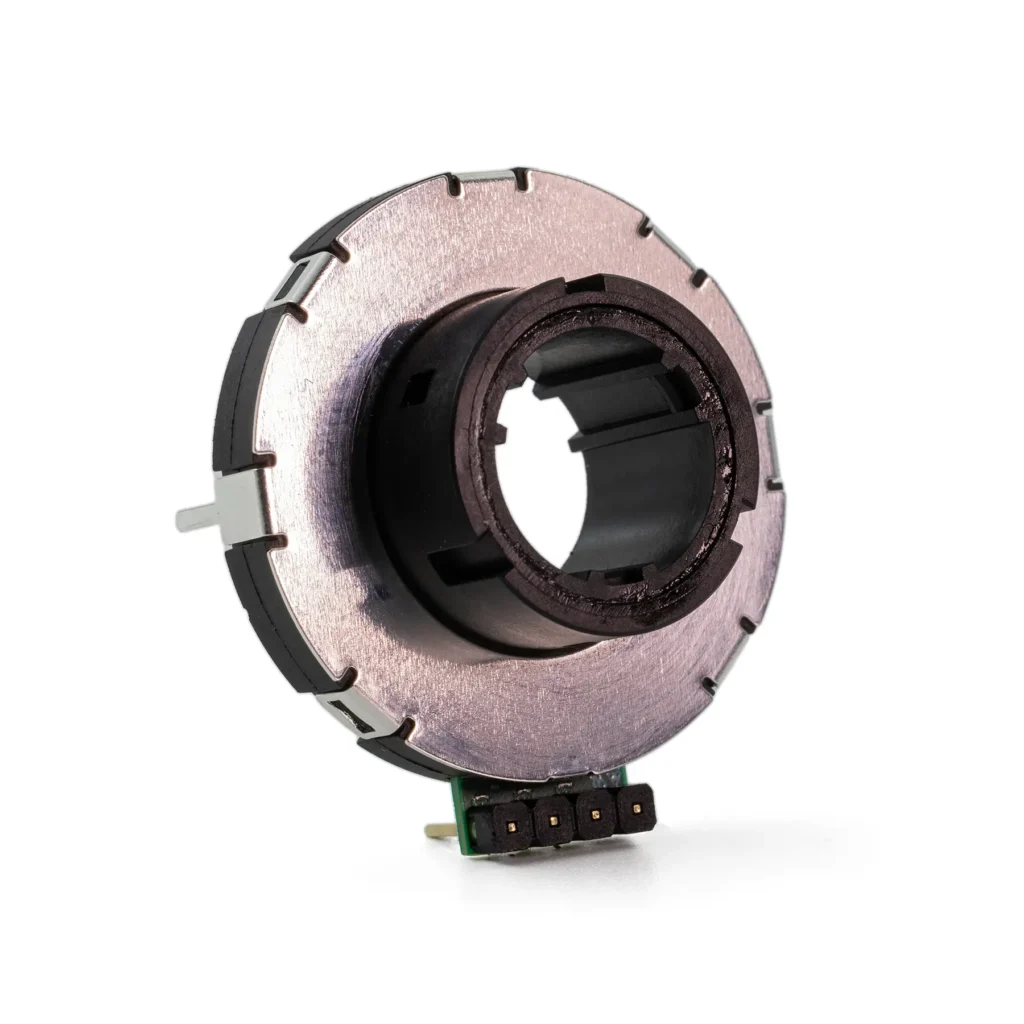

Seal Testing and Ingress Protection

Seal integrity is essential for protecting internal electronics from dust, water, chemicals, and airborne contaminants. Loss of seal performance can lead to corrosion, electrical shorts, sensor malfunction, or inconsistent tactile performance over time.

Grayhill performs seal testing according to standards such as:

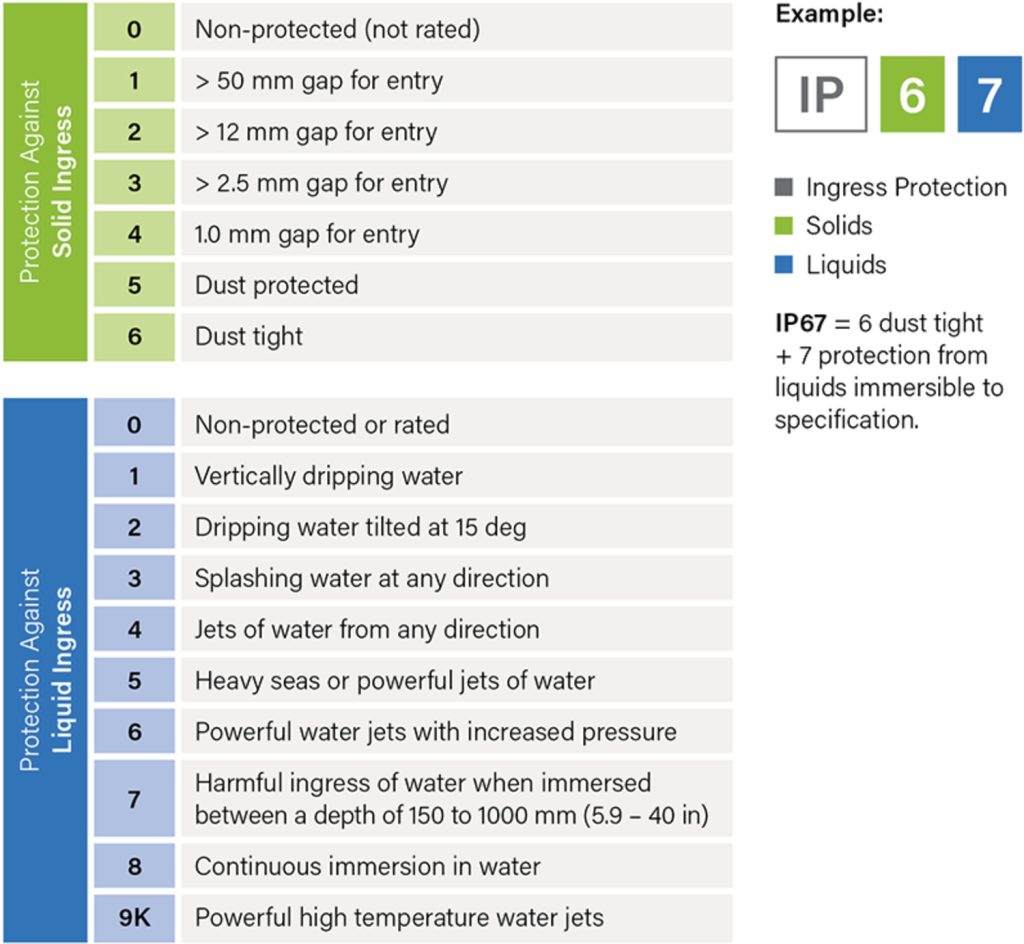

IEC 60529 (Ingress Protection or IP ratings)

Defines resistance to water and solid particle intrusion. Examples include:

- IP54 for limited dust ingress and splash resistance

- IP67 for complete dust protection and short-term immersion

- IP68 for deeper or longer immersion conditions depending on customer requirement

ISO 20653

Used extensively in automotive applications to evaluate dust and water exposure for road vehicles, including powerwash and mud splash environments.

Seal testing validates:

- Gasket and O-ring compression performance

- Housing and enclosure design integrity

- Effectiveness of sealing compounds or potting

- Long term durability of sealing interfaces

- Water or particle entry under pressure or immersion

Passing an ingress protection test does not guarantee lifetime seal performance. That is why Grayhill combines seal testing with environmental cycling, aging, vibration, and chemical exposure to evaluate how seals behave over time.

How Grayhill Uses Test Results to Improve Product Reliability

Corrosion, chemical exposure, and seal integrity are interrelated challenges. For example:

- A weakened seal can allow salt spray or chemicals to enter an enclosure

- Chemical swelling of a gasket may compromise water resistance

- Corrosion on electrical contacts may occur only after long term moisture exposure

By evaluating materials and assemblies under controlled laboratory conditions, Grayhill identifies vulnerabilities early and implements improvements such as:

- Selecting more corrosion resistant alloys or surface treatments

- Improving gasket geometry or compression force

- Choosing elastomers better suited for chemical compatibility

- Refining enclosure design to eliminate ingress pathways

- Adjusting plating thickness or coating selection

- Ensuring that mechanical interfaces resist degradation over time

This testing approach supports long term reliability, reduces field maintenance issues, and ensures consistent customer performance even in harsh environmental conditions.

Customer Advantages

For customers in outdoor equipment, aerospace, defense, medical, and industrial markets, this testing provides confidence that:

- Materials resist corrosion under expected environmental loads

- Assemblies remain sealed during handling, operation, and long term use

- Components withstand chemicals present in their application

- Surface finishes and markings remain legible and durable

- Connectors, switches, and interfaces continue operating reliably

- Failure risk is reduced through controlled validation

These evaluations help ensure that Grayhill products deliver stable performance throughout the full product life cycle.