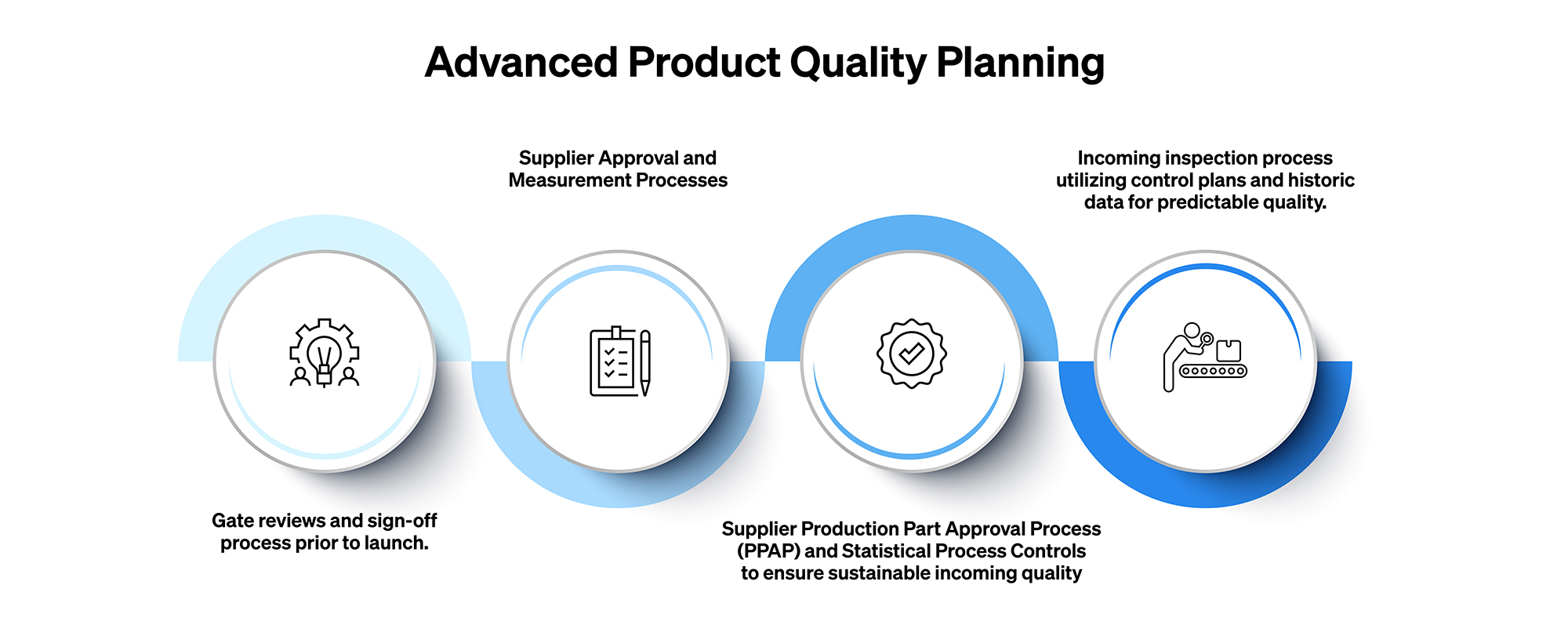

Quality begins long before a product is tested in a chamber or measured in a lab. It begins with a structured plan that ensures every design and manufacturing decision supports long-term reliability. At Grayhill, that structure is derived from Advanced Product Quality Planning (APQP).

APQP provides the framework for transforming customer needs into controlled processes, validated designs, and predictable product performance. This article explains what APQP is, why it matters, and how Grayhill uses it to reduce risk and strengthen product reliability from concept to launch.

What APQP Is and Where It Comes From

APQP originated when the Automotive Industry Action Group (AIAG) developed a standardized process for planning and controlling product quality during new product introduction. The goal was to reduce variation, eliminate preventable failures, and ensure suppliers could consistently meet customer specifications.

According to the AIAG, APQP focuses on:

- Understanding customer requirements

- Preventing issues rather than reacting to them

- Establishing robust process controls

- Ensuring product and process validation before launch

This approach has proven valuable across many industries where reliability and consistency matter, including aerospace, defense, medical, and industrial electronics.

Michael Abboud, Senior Quality Engineer, and Hana Dahir, Director of Corporate Quality

APQP Improves Product Reliability

Industry studies and case examples show that APQP can reduce scrap, lower defect rates, and improve first-time quality by identifying risks early and validating design and process decisions before production. Organizations that implement APQP often report better launch performance, fewer late-stage design changes, and more predictable product reliability. These proven benefits have helped APQP expand beyond automotive into sectors that require consistent performance and strict compliance.

Why APQP Matters for Grayhill Customers

For customers, APQP means that quality is planned, documented, measured, and verified before production begins. This reduces launch risk, accelerates development, and helps ensure that every Grayhill part performs as expected in the field.

APQP provides clear benefits such as:

- Better alignment between customer requirements and design decisions

- Early identification of potential failure modes

- More reliable product validation

- Smooth transition from prototype to production

- Fewer surprises, deviations, or delays during launch

The result is a product that meets expectations the first time and continues to meet them throughout its lifecycle.

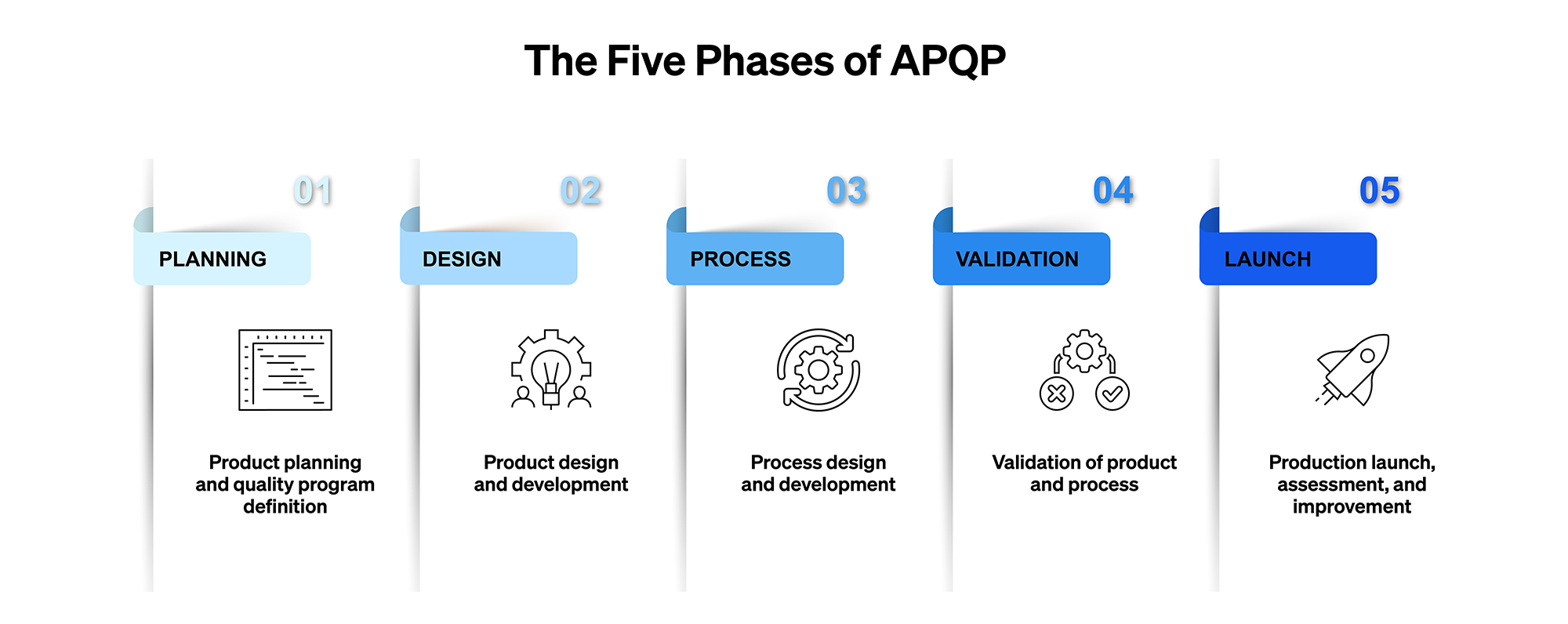

The Five Phases of APQP at Grayhill

Grayhill follows the classic five-phase APQP framework. Each phase builds on the last and helps create a strong foundation for quality before testing begins.

Phase 1: Planning

Grayhill begins by gathering requirements, defining quality objectives, and reviewing use cases. This includes customer specifications, regulatory standards, environmental expectations, and any known failure risks. Planning ensures everyone understands what the product must achieve and how success will be measured.

Phase 2: Product Design and Development

Engineering teams develop the design while simultaneously evaluating potential failure points using tools such as DFMEA. Design reviews evaluate functionality, safety, manufacturability, and compliance. The goal is to create a design that meets customer requirements and can be produced consistently.

Phase 3: Process Design and Development

Once the design is established, Grayhill defines how the product will be built. This includes process flow diagrams, PFMEA, control plans, and tooling development. Supplier readiness is confirmed through PPAP when required. At this stage, many issues can still be prevented before production equipment is finalized.

Phase 4: Validation of Product and Process

The product and process are tested together to confirm performance and repeatability. This includes dimensional verification, functional testing, environmental validation, capability studies, and production trial runs. Validation helps ensure the process consistently meets specifications before the official launch.

Phase 5: Launch, Assessment, and Continuous Improvement

Once validation is complete, the product moves into production, with ongoing monitoring of capabilities, inspections, and feedback loops. Continuous improvement allows Grayhill to refine processes, reduce defects, and maintain consistent quality throughout the product life.

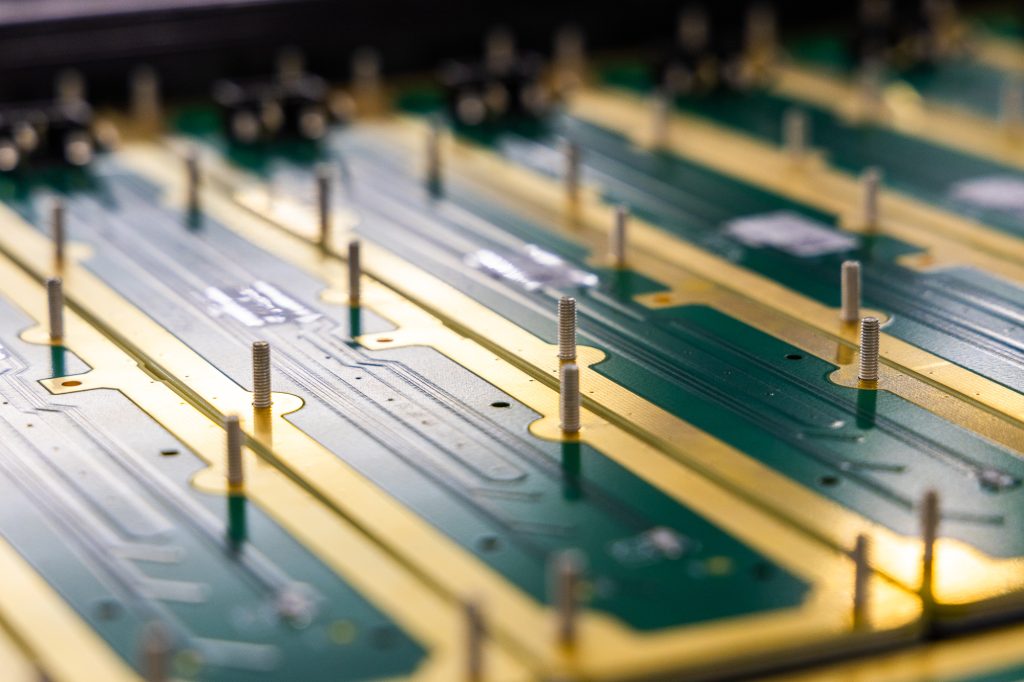

How APQP Strengthens Later Testing

Environmental, mechanical, electrical, and lifecycle tests are only meaningful when the design and the process behind the product are stable. APQP provides that stability.

With APQP in place, testing reflects the true performance of the product, not uncontrolled variation. It also ensures that testing is performed on parts that reflect the actual production process, supporting a realistic evaluation of long-term reliability.

When customers see test results from Grayhill, they can trust the product has been validated through a controlled, repeatable process.

What This Means for Customers

APQP allows Grayhill to deliver:

- Reliable performance across every build

- Faster, more efficient program launches

- Greater traceability and documentation

- Controlled processes from early concept through full production

- Lower risk of defects or failures in the field

Quality is not inspected in. It is planned in. APQP ensures that every Grayhill product starts with a disciplined foundation that makes later testing and validation more meaningful.