Rotational Control: Hall-Effect Sensor and Switches Manufacturing

In the dynamic world of industrial manufacturing, precision and efficiency are paramount. At the heart of this precision lies the critical role of rotational control technologies, particularly the encoder, the Hall-effect switch, and the Hall-effect sensor.

Introduction to Rotational Control Technology

These components are vital in various applications, ranging from automation to motion control systems. This comprehensive guide aims to demystify these technologies, focusing on their unique capabilities, applications, and how choosing the right partner for these components can elevate your manufacturing processes.

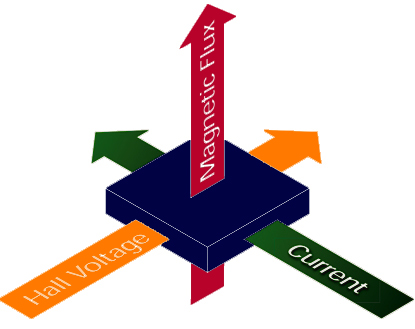

Understanding the Hall Effect

The Hall-effect sensor operates as a magnetic field detector. It functions by outputting a voltage in response to a magnetic field. This unique capability makes it invaluable in various industrial applications, including position sensing, speed detection, and proximity switching.

Advantages of These Sensors

- Durability and Reliability: With no moving parts, these sensors are highly durable and reliable, ideal for harsh industrial environments.

- Versatile Applications: Their ability to detect magnetic fields non-invasively allows for diverse applications, including fluid flow measurement and rotational speed detection.

- Cost-Effective Solution: Generally, a Hall-effect sensor is more affordable than encoders, making them a budget-friendly option for many applications.

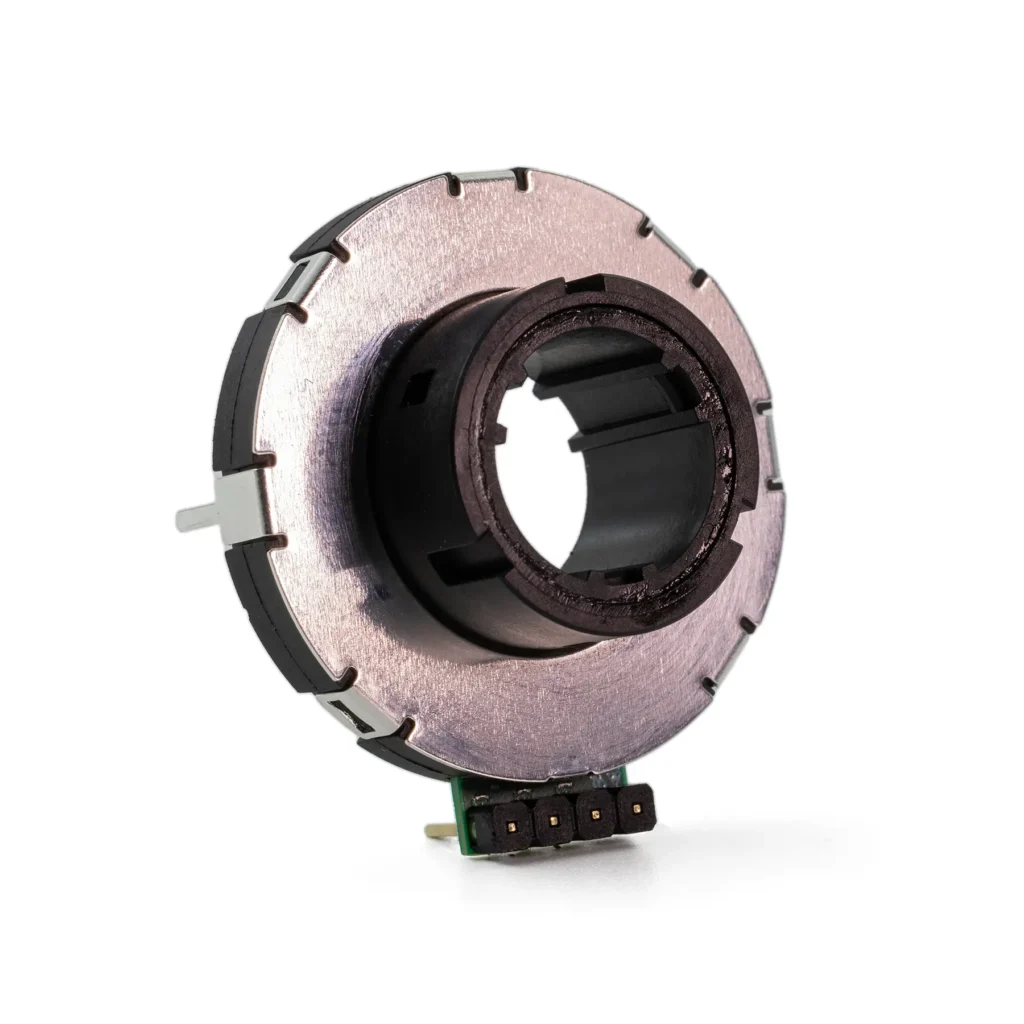

Exploring Encoders

Encoders convert mechanical motion into electrical signals, offering detailed information about position, speed, and direction. They are essential in applications demanding high precision, such as robotic control systems and complex machinery.

Advantages of Encoders

- High Resolution and Precision: Encoders are capable of providing extremely high-resolution data, crucial for applications requiring meticulous accuracy.

- Directional Awareness: They can determine the direction of rotation, an attribute lacking in Hall-effect sensors.

- Application Flexibility: Available in various configurations like absolute and incremental, encoders cater to a wide range of industrial applications.

Considerations with Encoders

- Complexity and Maintenance: They may have more moving parts, potentially leading to higher maintenance requirements. The right partner is key.

- Size and Expense: Encoders can be bulkier and more costly, which might be a constraint in certain applications.

- Environmental Sensitivity: Optical encoders, in particular, are susceptible to accuracy issues in dirty or dusty environments.

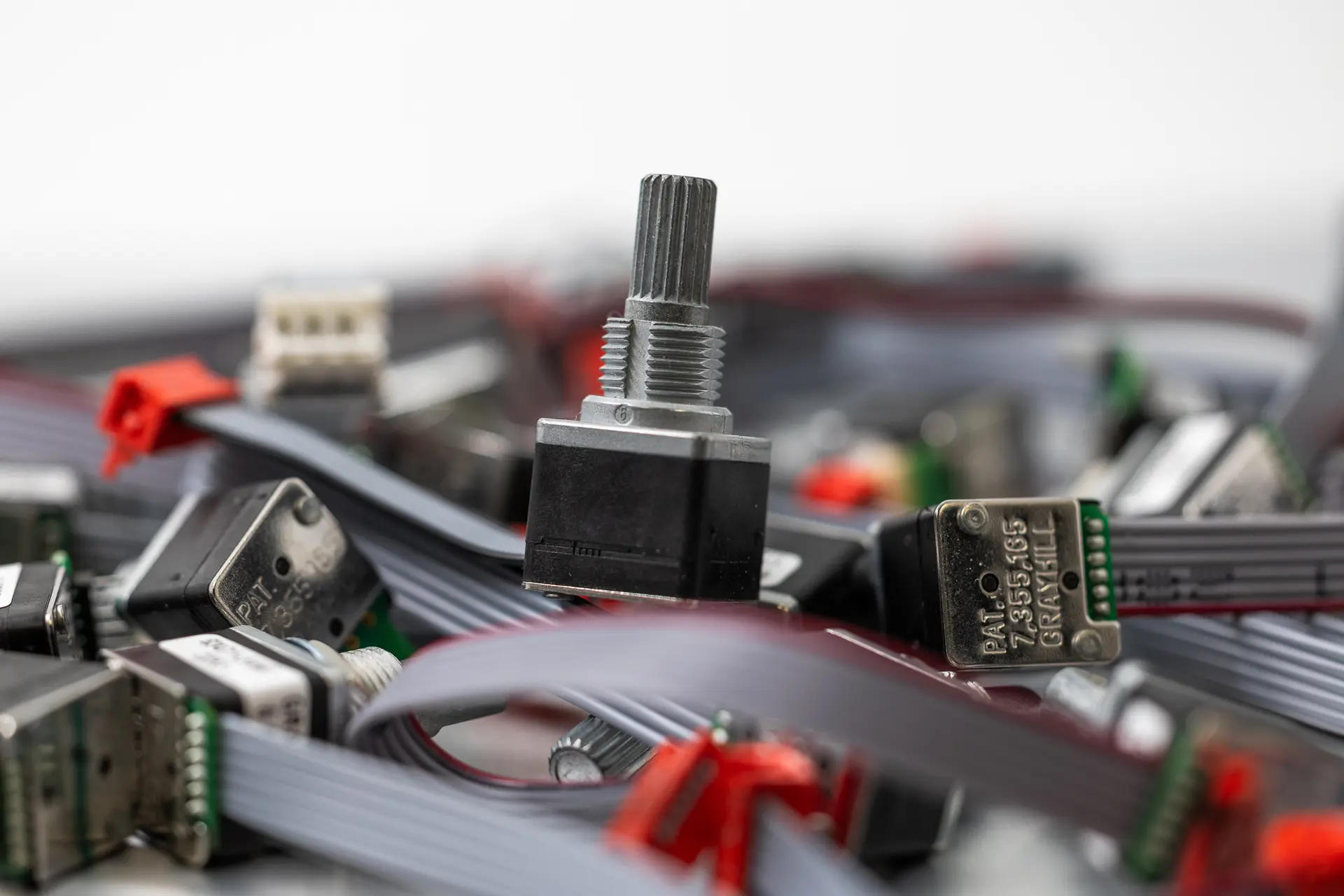

Key Features of a Hall-Effect Switch

A Hall-effect switch is a specific type of Hall-effect sensor that operates as a binary switch. It is designed to detect the presence or absence of a magnetic field and switch its output from one state to another, typically from off to on or vice versa. This makes it ideal for applications that require simple on-off detection, such as position sensing, proximity detection, or speed measurement.

- Non-Contact Operation: Like other Hall-effect sensors, Hall-effect switches detect magnetic fields without requiring physical contact. This feature enhances their durability and longevity as they are less susceptible to wear and tear from moving parts.

- High Sensitivity: These switches can detect very slight changes in magnetic field strength, making them highly precise in applications where such sensitivity is necessary.

- Binary Output: They provide a simple binary output (on/off), which is easy to interface with other electronic components and systems. This simplicity makes them ideal for straightforward applications.

- Robustness: They are generally robust against environmental factors such as dust, moisture, and temperature variations, making them suitable for use in a wide range of industrial environments.

- Compact Size: Hall-effect switches are typically small and can be easily integrated into various systems without requiring much space.

Applications of a Hall-Effect Switch in Industry

- Position Sensing: They are used to detect the presence or absence of an object, for example, in safety interlocks, or to confirm that a component is in the correct position before an operation proceeds.

- Proximity Detection: In applications where it's necessary to detect the presence of an object without physical contact, such as in safety barriers or counting systems.

- Speed Measurement: Hall-effect switches can detect the speed of a rotating object by counting the number of times a magnetic field passes by the sensor within a given time frame.

- End-Stop Detection: In machinery and equipment, Hall-effect switches are used to detect the end of a travel range, preventing moving parts from exceeding their intended path.

Choosing the Right Hall-Effect Switch for Your Application

When selecting a Hall-effect switch, consider the following:

- Magnetic Field Strength: Ensure the switch is sensitive enough for the magnetic field strength in your application.

- Environmental Conditions: Choose a switch that can withstand the environmental conditions it will be exposed to, such as temperature extremes or the presence of contaminants.

- Switching Speed and Accuracy: Depending on your application, the speed and accuracy of the switch can be critical factors.

- Output Type: Determine the required output type (e.g., NPN, PNP, open collector) for compatibility with your system.

In brief, a Hall-effect switch is a versatile and reliable component in various industrial applications. Their simplicity, durability, and precision make them a popular choice for tasks requiring straightforward, binary detection of magnetic fields.

Synergy in Rotational Control

To sum it up, encoders, sensors, and switches have distinct roles in the realm of industrial manufacturing, each with unique strengths and limitations. The key to maximizing their potential lies in understanding these differences and choosing a supplier that can provide the right solution tailored to your specific needs.

By doing so, you can ensure smooth, efficient, and precise operations in your manufacturing processes, harnessing the full power of these remarkable rotational control technologies.

Remember, it's not just about the individual components; it's about creating a cohesive system that aligns with your operational goals. The right partner will help you navigate this journey, ensuring that your machinery and processes operate at their optimal best, leading to enhanced productivity and success in your industrial endeavors.

Strategic Insights for Business Buyers in Rotational Control

As a business buyer, your decision extends beyond choosing between a Hall-effect sensor and encoders. It's about finding a supplier that aligns with your company's values, technical needs, and long-term goals. This section offers a roadmap for selecting the right supplier, emphasizing the importance of quality, reliability, and partnership in achieving optimal rotational control.

Look for suppliers that don't just distribute components but understand their intricate workings and applications. This expertise is vital in tailoring solutions to your specific industrial needs. Assess their capability to provide custom solutions, especially for unique or complex applications.

Quality should never be a compromise. Select suppliers known for their adherence to high. A supplier invested in innovation and technological advancement is a valuable asset. They can provide access to the latest technologies and improvements in rotational control.

Conclusion: Building Partnership for Rotational Control Excellence

Selecting the right supplier for encoders and Hall-effect sensors is about forming a strategic partnership. It involves a deep understanding of your operational needs, an appreciation for the technological nuances of these components, and a commitment to long-term success. By considering these factors, you can establish a relationship with a supplier that not only meets your current requirements but also supports your future growth and innovation in the field of industrial manufacturing.

The journey to optimal rotational control in industrial applications is multifaceted. It requires careful consideration of the technical aspects of encoders and the Hall-effect sensor, balanced with a strategic approach to supplier selection. The right partner will not only provide high-quality components but also offer the expertise, support, and innovation necessary to keep your operations running smoothly and efficiently.

The process of selecting the right components and suppliers is not just a transaction but an investment in the future of your business. By making informed choices, you position your company to thrive in a competitive, technology-driven market, ensuring that you stay ahead of the sensor and switch technology. Contact Grayhill or explore our Hall-effect encoders to learn more.