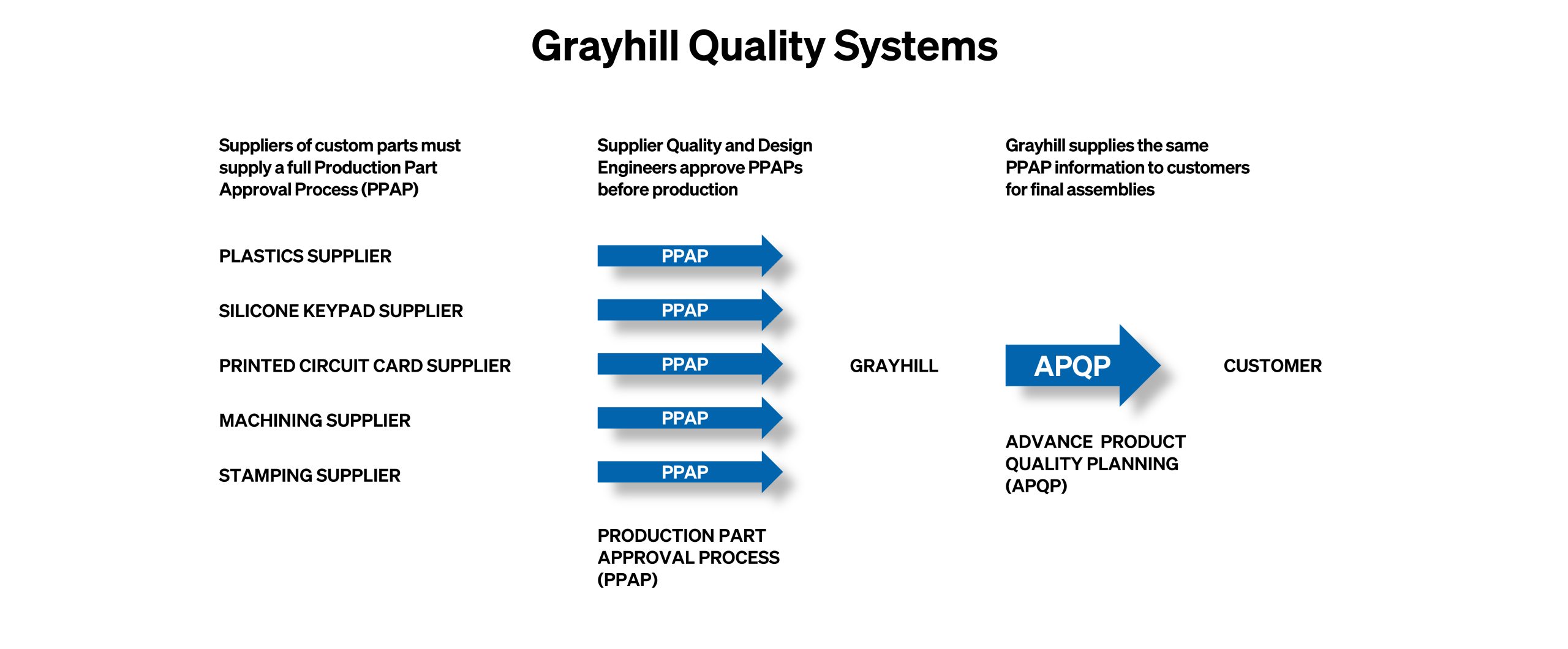

Every high-performance product depends on the strength of its supply chain. Even the best internal processes cannot overcome inconsistent or poorly controlled inputs. This is why Grayhill places significant focus on supplier quality and requires structured methods such as Production Part Approval Process, Process Failure Mode and Effects Analysis, and Control Plans. These tools help ensure that every supplied component meets specification, is produced through a capable process, and supports long-term product reliability.

In high-reliability markets such as aerospace, defense, medical, automotive, and industrial electronics, suppliers must prove that their processes are capable, their designs are sound, and their controls can sustain quality over time. This blog explains how Grayhill uses PPAP, PFMEA, and Control Plans to create predictable, traceable, and stable supplier performance.

Why Supplier Quality Matters Before Testing Begins

Reliable products depend on consistent inputs. A well-designed part fails if the material or dimensions vary from run to run. An advanced assembly becomes unreliable if upstream variability exceeds tolerance limits. Testing can confirm performance, but only stable supplier processes ensure that performance is repeatable.

Grayhill requires suppliers to demonstrate that their processes are capable and controlled before production begins. This reduces downstream variation, lowers risk during product validation, and prevents costly quality escapes during full-scale manufacturing.

What PPAP Means for Grayhill Suppliers

A Production Part Approval Process (PPAP) verifies that a supplier can consistently produce a part that meets all engineering and specification requirements. It is widely used in automotive and industrial sectors to validate tooling, processes, documentation, and repeatability.

Grayhill requires a full Level 1 PPAP for all new tooled parts. This includes:

- First article inspection of all dimensions

- Capability studies (CPK) for critical characteristics

- Detailed process flow diagrams

- DFMEA and PFMEA to assess potential failure points

- Measurement system analysis to confirm accuracy

- Control plans that define how quality will be monitored during production

The purpose of PPAP is simple. Before production begins, suppliers must show that their tooling and processes can reliably produce parts within tolerance. This prevents issues that would otherwise appear only after launch, when costs and risks are higher.

The Role of PFMEA in Preventing Failures

A Process Failure Mode and Effects Analysis (PFMEA) identifies where a process might fail and how severe that failure could be. It examines each step in the manufacturing process and asks structured questions such as:

- What could go wrong at this step

- How likely is it to occur

- How severe would the effect be

- How quickly would the issue be detected

PFMEA supports continuous improvement by highlighting process weaknesses, guiding mitigations, and documenting corrective actions. For Grayhill, PFMEA ensures suppliers have assessed and controlled risks before any part enters validation.

A strong PFMEA reduces variation, reinforces process stability, and increases confidence in long-term performance.

How Control Plans Ensure Ongoing Stability

A Control Plan defines how a supplier monitors quality during production. It lists every critical characteristic, its measurement method, the sampling frequency, the acceptance criteria, and the reaction plan if a measurement is out of specification.

For Grayhill, control plans provide the structure for continuous compliance. They ensure:

- Process consistency across shifts and production lots

- Documentation of every inspection and measurement

- Defined responses when variation occurs

- Long-term repeatability for high-reliability applications

Control Plans turn quality expectations into daily practice. Without them, even a validated process can drift over time. With them, suppliers maintain predictable output and reliable components throughout the product lifecycle.

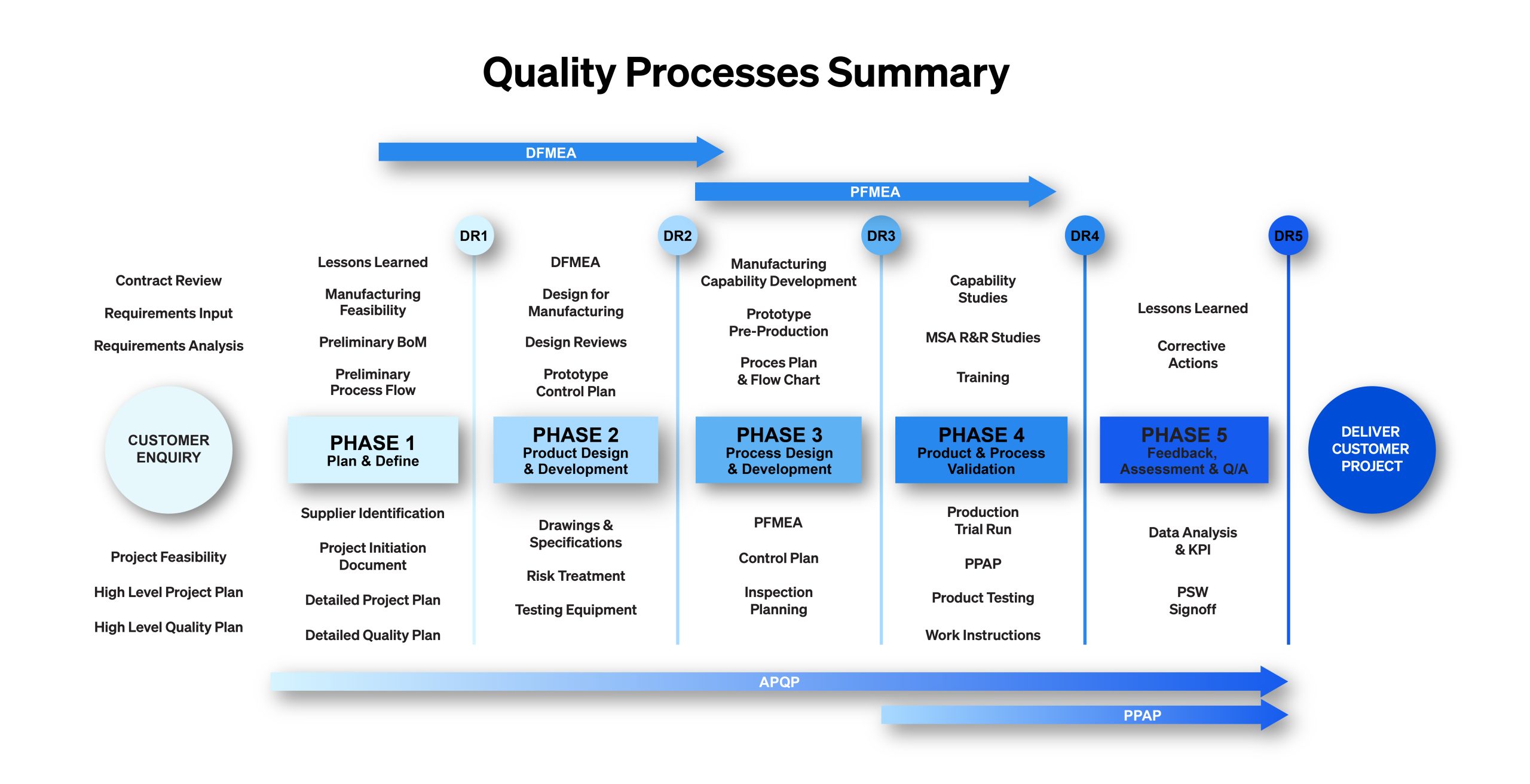

How PPAP, PFMEA, and Control Plans Work Together

These tools complement each other.

- PPAP confirms that the process is ready and capable.

- PFMEA ensures the risks are understood and mitigated.

- Control Plans keep the process stable through ongoing monitoring.

Together, they create a proactive quality system rather than a reactive one. They prevent issues before they reach Grayhill facilities, strengthen testing accuracy by providing consistent inputs, and reduce the risk of variation during full production.

What This Means for Customers

Grayhill customers benefit from supplier quality requirements through:

- Higher confidence in material and component consistency

- Reduced risk of defects entering the assembly process

- Greater traceability and documentation

- More stable product performance in demanding environments

- Fewer delays during validation and production ramp-up

Supplier quality is one of the strongest indicators of product reliability. By enforcing PPAP, PFMEA, and Control Plans across all tooled suppliers, Grayhill ensures quality begins at the source.