Mechanical shock testing evaluates how a product responds to sudden, high intensity forces that occur during handling, transport, installation, or operational use. Unlike vibration testing, which applies continuous energy over time, mechanical shock delivers a short duration pulse that can create immediate structural or functional damage. These events are unpredictable in the field but must be accounted for during qualification to ensure long term reliability.

Mechanical shock is especially important for products used in defense, aerospace, automotive, medical, industrial, and off highway environments, where equipment must continue to operate despite drops, collisions, abrupt starts and stops, or extreme field conditions.

Why Mechanical Shock Testing Matters

Mechanical shock introduces rapid acceleration and deceleration forces. These forces can exceed the strength of weaker joints, interfaces, or materials, revealing vulnerabilities that slow, repetitive stress may not expose.

Typical issues that shock testing uncovers include:

- Cracked housings or mechanical fractures

- Broken or fatigued solder joints

- Dislodged internal components

- Loosened connectors or terminals

- Damaged fasteners or mounting points

- Temporary or permanent functional interruption

- Relays or switches that bounce or misfire

- Electrical discontinuities caused by momentary contact loss

Shock testing provides insight into how a design responds to real world impact events and helps engineers confirm that a product will not fail prematurely during transport or operation.

Where Mechanical Shock Occurs in Real Applications

Mechanical shock events happen in more places than most users expect. Examples include:

- Equipment dropped during maintenance or installation

- Vehicle mounted electronics exposed to potholes or abrupt impacts

- Aerospace systems experiencing landing shock

- Industrial equipment struck by tools or moving machinery

- Components on forklifts or construction vehicles that encounter abrupt stops

- Avionics or defense hardware exposed to explosive shock environments

- Medical equipment encountering drops in clinical settings

Understanding these scenarios allows Grayhill engineers to choose appropriate shock profiles and test severities.

Standards That Guide Mechanical Shock Testing

Mechanical shock testing is defined by several industry standards that provide structured methods for evaluating product response.

- MIL STD 810 Method 516

This standard defines multiple shock procedures, including:

-

- Operational shock

- Crash hazard shock

- Bench handling shock

- Transit drop shock

- Functional shock during powered conditions

MIL STD 810 emphasizes tailoring shock severity to the expected use environment, including peak acceleration, pulse duration, and orientation of the equipment during testing.

- IEC 60068 2 27

This standard specifies:

-

- Shock pulse waveforms such as half sine or trapezoidal

- Peak acceleration levels

- Pulse durations

- Number of shocks per axis

IEC shock tests are commonly used for component level validation in electronics and electromechanical assemblies.

- ISO 16750 3

Primarily used in automotive applications, this standard provides:

-

- Shock sequences that simulate road events

- Energy levels for powered and unpowered states

- Mounting orientation guidance

- Vehicle specific design considerations

ISO 16750 shock testing helps validate components used in trucks, passenger vehicles, agricultural equipment, and construction machinery.

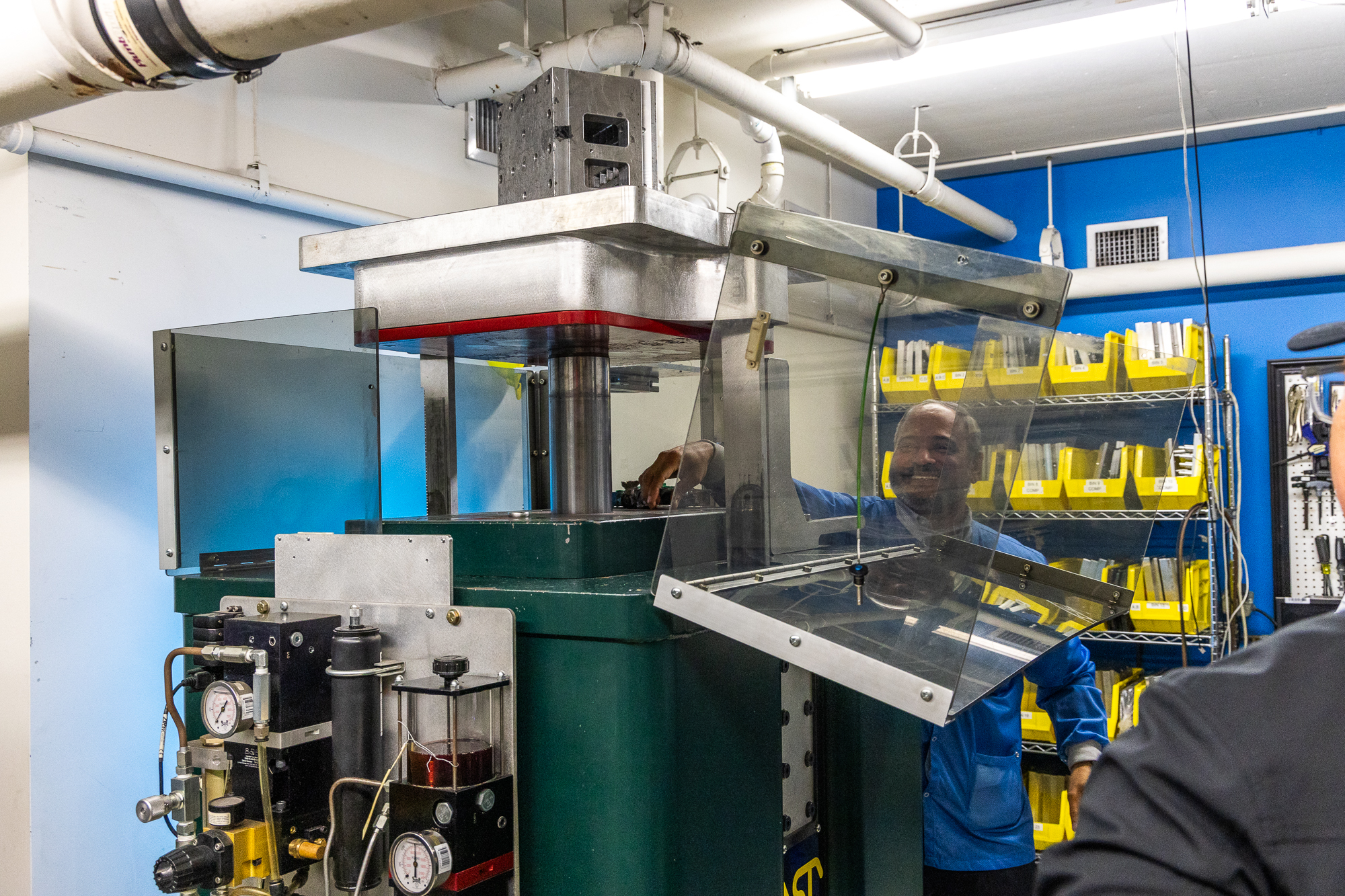

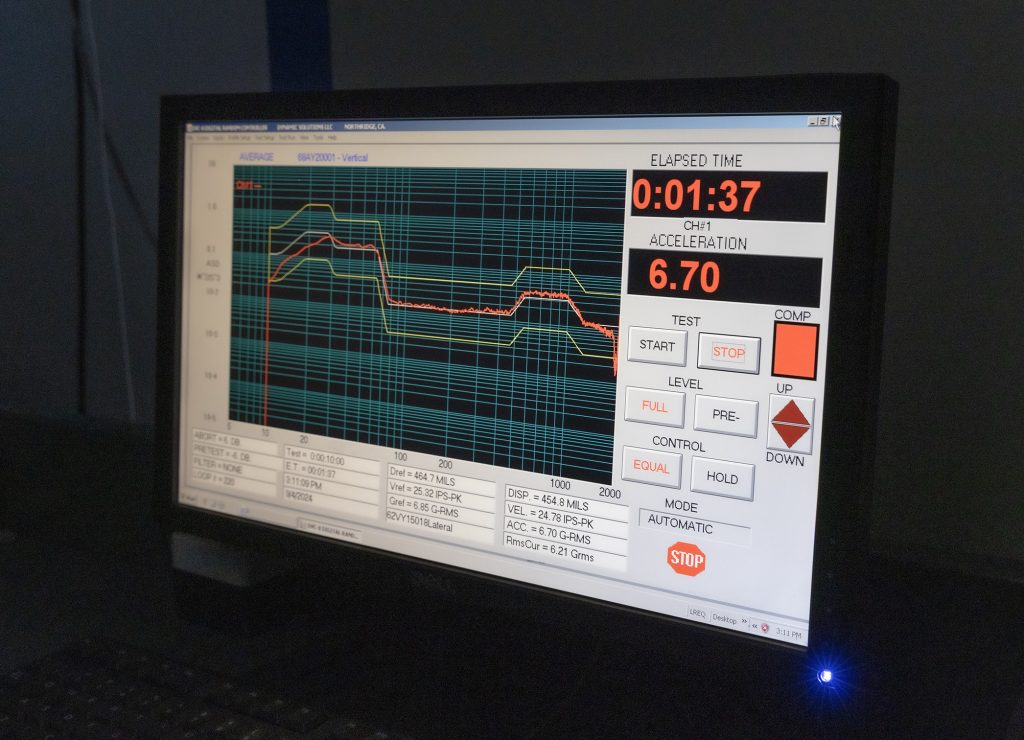

How Mechanical Shock Testing Is Performed at Grayhill

Grayhill uses precision mechanical shock platforms capable of delivering controlled shock pulses with repeatable acceleration and duration. The test setup is defined by:

- Mounting configuration

Products are mounted as they would be used in the field. - Orientation

Shocks are applied along multiple axes to simulate realistic impact directions. - Pulse waveform

Common waveforms include half sine, sawtooth, and trapezoidal pulses. - Peak acceleration and duration

Higher acceleration increases severity, while shorter duration represents more abrupt impacts. - Number of shocks

Typically multiple pulses are applied in each axis to evaluate cumulative effects.

During and after testing, Grayhill engineers evaluate:

- Structural integrity and mechanical stability

- Actuator performance and tactile behavior

- Electrical continuity and signal stability

- Functional response and reset behavior

- Connector retention and interconnect reliability

- Visual inspection for cracks, deformation, or displacement

Any deviation from expected performance can indicate a structural weakness, design flaw, or material compatibility issue.

Failure Modes Mechanical Shock Can Reveal

Mechanical shock often exposes weaknesses that normal operation or vibration does not. These include:

- Fastener failure

Screws or clips may loosen or deform under high stress. - Connector disengagement

Poor retention or tolerance issues become apparent. - PCB displacement or fracture

High acceleration can cause corner cracking or trace damage. - Relay bounce or contact chatter

Mechanical switches can misfire under sudden stress. - Internal mass resonance

Heavy components may detach if not properly reinforced.

Understanding these modes helps engineers refine mechanical design, choose better mounting strategies, or adjust material selection.

How Shock Data Improves Product Design

Shock testing is not only a qualification step but also a design improvement tool. Insights gained from testing help engineers strengthen housings and internal structures, select more robust solder alloys or interconnects, improve connector retention forces, optimize mounting hardware, and reinforce PCBs or internal assemblies.

The results also allow engineers to predict potential field failures and address them before a product is released. By integrating shock test data early, Grayhill ensures that each product can withstand the stresses of handling, installation, transport, and operation.

Why Mechanical Shock Testing Builds Customer Confidence

Mechanical shock testing provides customers with assurance that Grayhill products will continue to perform reliably even in demanding or unpredictable environments. The results demonstrate increased durability during transport and installation, reduced field failures caused by accidental impacts, and improved performance in rugged or high vibration settings.

Customers gain confidence knowing that connectors, solder joints, and mechanical interfaces remain stable under sudden force, and that the product will deliver consistent performance over its full life cycle. For organizations working in mission critical or safety critical applications, this level of reliability is essential.