CAN-Based HMI Solutions for Modern Defense Vehicles

As defense platforms become increasingly connected and electronically sophisticated, the demand for intelligent, flexible, and rugged control systems continues to grow. Modern tactical vehicles rely on complex electronic architectures to manage power distribution, communications, sensors, and mission systems. To support this complexity while maintaining reliability, many defense programs are standardizing on CAN-based (Controller Area Network) communication architectures.

CAN bus technology enables distributed control systems to operate efficiently in harsh environments, making it well suited for military vehicle applications. As a result, human–machine interface (HMI) components that integrate seamlessly with CAN-based systems are becoming a critical part of vehicle design.

Grayhill designs and manufactures CAN-enabled HMI solutions engineered to meet the demanding requirements of defense vehicles, supporting reliable operation while simplifying system integration for program and platform engineers.

Why CAN Bus Is Widely Used in Defense Vehicles

Originally developed for automotive applications, CAN bus has been widely adopted across defense and tactical vehicle platforms due to its robustness, flexibility, and efficiency. In military environments where space, weight, and reliability are critical, CAN-based architectures offer several key advantages.

Key Benefits of CAN Bus:

- Reduced wiring complexity

CAN bus allows multiple devices to communicate over a shared data bus, significantly reducing cabling, connectors, and overall system weight. This simplification improves reliability and eases maintenance. - Improved system interoperability

By enabling standardized communication between subsystems, CAN bus supports integration of displays, controls, sensors, and mission electronics within a unified architecture. - Real-time diagnostics and data exchange

CAN bus supports real-time monitoring, diagnostics, and fault reporting, which is critical for vehicle health management and mission readiness. - Protocol compatibility

CAN bus is compatible with widely used protocols such as SAE J1939 and CANopen, allowing defense programs to leverage existing standards and tools.

These characteristics make CAN bus particularly effective for distributed vehicle control systems, where multiple HMI devices must operate reliably under vibration, temperature extremes, and electromagnetic interference.

The Role of HMI in CAN-Based Defense Architectures

In a CAN-based system, the HMI serves as the primary interface between the operator and vehicle systems. Displays, keypads, switches, encoders, and joysticks must not only communicate reliably on the network, but also provide intuitive, immediate feedback to the operator.

For defense applications, HMI design must account for:

- Gloved operation

- Limited visibility and night operations

- High vibration and shock loads

- Rapid operator response under stress

CAN-enabled HMI components allow designers to distribute control functions throughout the vehicle while maintaining centralized data exchange and diagnostics.

Grayhill’s CAN-Based HMI Solutions

Grayhill offers a range of rugged HMI components designed for CAN-based defense systems, supporting both new vehicle programs and modernization of legacy platforms.

CAN Bus Displays

Grayhill’s CAN-enabled displays provide real-time feedback and control for vehicle subsystems, enabling operators to monitor system status, configure settings, and respond quickly to changing conditions.

CAN-Integrated Keypads

Keypads with integrated CAN interfaces simplify input architecture by reducing discrete wiring and allowing direct communication with vehicle networks. These keypads can be customized for layout, legends, and illumination to meet specific platform requirements.

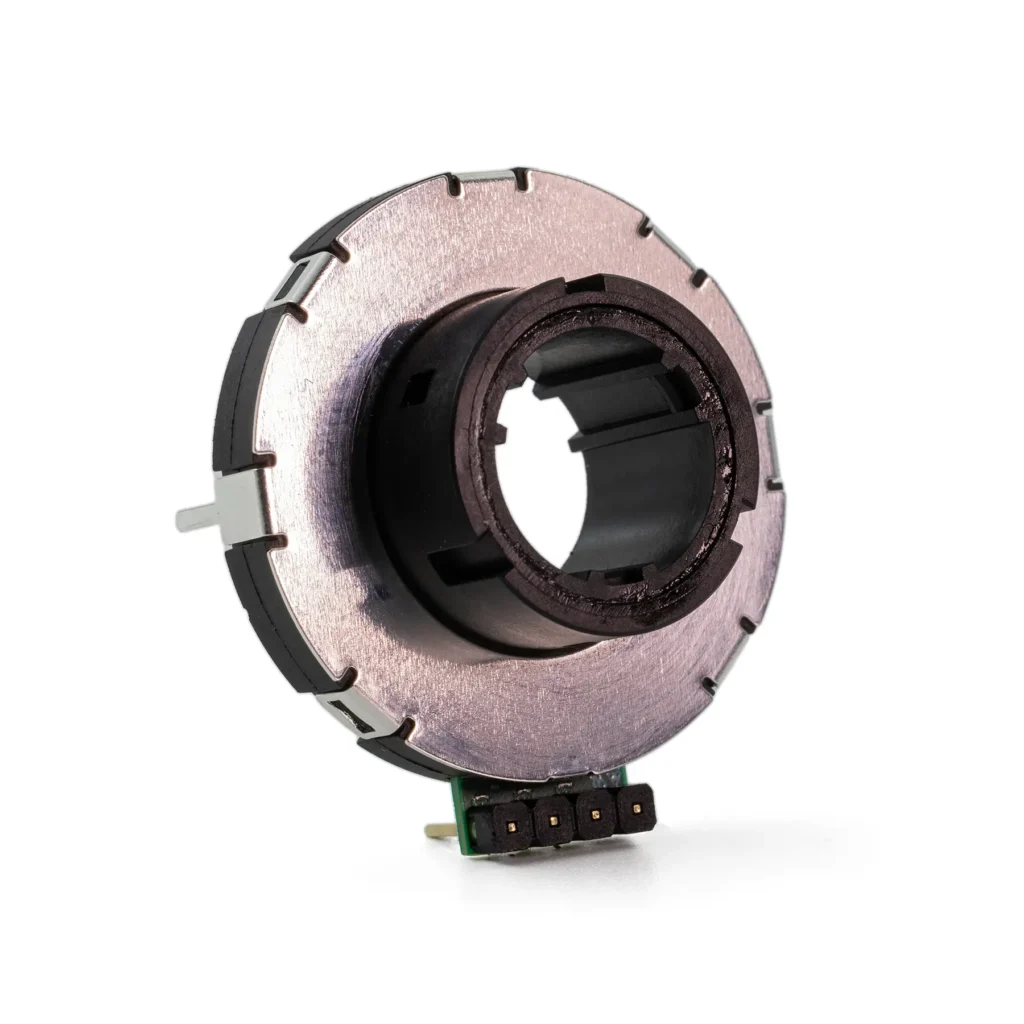

Rotary Encoders and Joysticks

Grayhill rotary encoders and joysticks can be incorporated into custom control panels for CAN-based systems, providing precise input for functions such as navigation, communications, and system selection. These components support flexible integration while maintaining tactile feedback critical for eyes-off operation.

Engineered for Harsh Defense Environments

All Grayhill CAN-enabled HMI solutions are designed with ruggedization as a core requirement, not an afterthought. Products are engineered to withstand:

- Shock and vibration common to tactical vehicles

- Wide temperature extremes encountered in deployed environments

- Dust, moisture, and environmental exposure

- EMI/EMC conditions present in dense electronic architectures

This level of durability makes Grayhill HMI components well suited for tactical crew stations, command vehicles, and field-deployed platforms where reliability directly impacts mission success.

U.S. Marine Corps photo by Lance Cpl. Drake Nickels

Supporting New Programs and Legacy Vehicle Upgrades

CAN-based HMI solutions play an important role not only in next-generation vehicle development, but also in retrofitting and upgrading legacy platforms. By integrating CAN-enabled controls and displays, defense programs can modernize vehicle functionality without complete system redesign.

Grayhill’s modular, configurable approach allows engineers to tailor HMI solutions to specific vehicle architectures while maintaining long-term support and consistency across production and sustainment phases.

Designing for Program Longevity

Defense vehicle programs often remain in service for decades. HMI components must support long service life, documentation requirements, and sustainment planning. Grayhill designs its CAN-based HMI solutions with these realities in mind, helping defense customers reduce lifecycle risk and support long-term operational readiness.

Mission-Ready CAN-Based HMI for Defense Vehicles

As military vehicles continue to evolve toward more connected and distributed electronic architectures, CAN-based HMI solutions will remain central to reliable vehicle operation. By combining CAN bus integration with rugged, operator-centric design, Grayhill delivers HMI components that meet the technical, environmental, and lifecycle demands of modern defense platforms.