At Grayhill, quality is our culture. Before we build a single part or run a lab test, we build a quality system. That system gives our customers confidence that every product from the first prototype to the finished assembly meets rigorous standards for reliability, safety, and consistency. In this article, we will explain why certifications such as ISO 9001 and AS9100 matter and how they underpin everything we do at Grayhill.

What ISO 9001 is, and Why it Matters

ISO 9001 is the most widely adopted quality management system standard worldwide. It provides a framework to ensure consistent, high-quality outputs across industries.

According to ISO, the standard promotes:

- A process-based approach to operations, ensuring that every step from design through delivery is documented, controlled, and repeatable.

- A commitment to continuous improvement. This helps organizations adapt, refine processes over time, and reduce defects, waste, and inefficiency.

- A strong focus on customer satisfaction. This ensures that products meet customer requirements, regulatory demands, and performance expectations.

For any manufacturer, ISO 9001 certification signals a mature quality management system behind every product. It demonstrates structure, discipline, and accountability instead of relying on effort alone.

Why AS9100 Adds Another Layer for Aerospace, Defense, and High Reliability Applications

While ISO 9001 provides a strong foundation, industries with higher safety and reliability requirements need more than general quality controls. AS9100 meets that need. This standard builds on ISO 9001 and adds requirements specific to aerospace, defense, and other high-reliability sectors.

Industry resources highlight that AS9100 strengthens quality systems by adding:

- Risk management and safety requirements

Risk-based thinking must be built into design, supply chain selection, production, inspection, and documentation. - Supply chain and traceability controls

AS9100 ensures traceability of materials and components, strong supplier vetting, and processes to prevent counterfeit or nonconforming parts. - Documentation, configuration management, and change control

Every change in design or process must be documented and controlled to ensure consistency across time and across production runs. - Focus on product safety and reliability across the entire lifecycle

This includes durability, defect prevention, and performance standards that reflect real-world operating conditions.

For a company like Grayhill, which manufactures components for demanding environments, AS9100 certification is often not optional. It satisfies customer and industry requirements in aerospace, defense, and other regulated markets.

What Certification Means for Grayhill Customers

Because Grayhill is built on ISO 9001 and AS9100, our customers benefit in several important ways:

- Consistent Quality

Every part, production run, and product configuration is produced through controlled, repeatable processes. - Lower Risk

With strong traceability, process control, and supplier oversight, the risk of unexpected failures or quality issues is significantly reduced. - Reliability and Long Product Life

From raw material selection to final assembly, every step is controlled. Customers can trust long-term performance even in harsh or critical environments. - Regulatory Confidence and Market Access

Customers in aerospace, defense, and other regulated industries can rely on Grayhill to meet or exceed required standards. - Continuous Improvement

Quality at Grayhill evolves over time. Through audits, inspections, and data-driven reviews, we refine and improve our processes.

How This Foundation Supports Testing and Validation

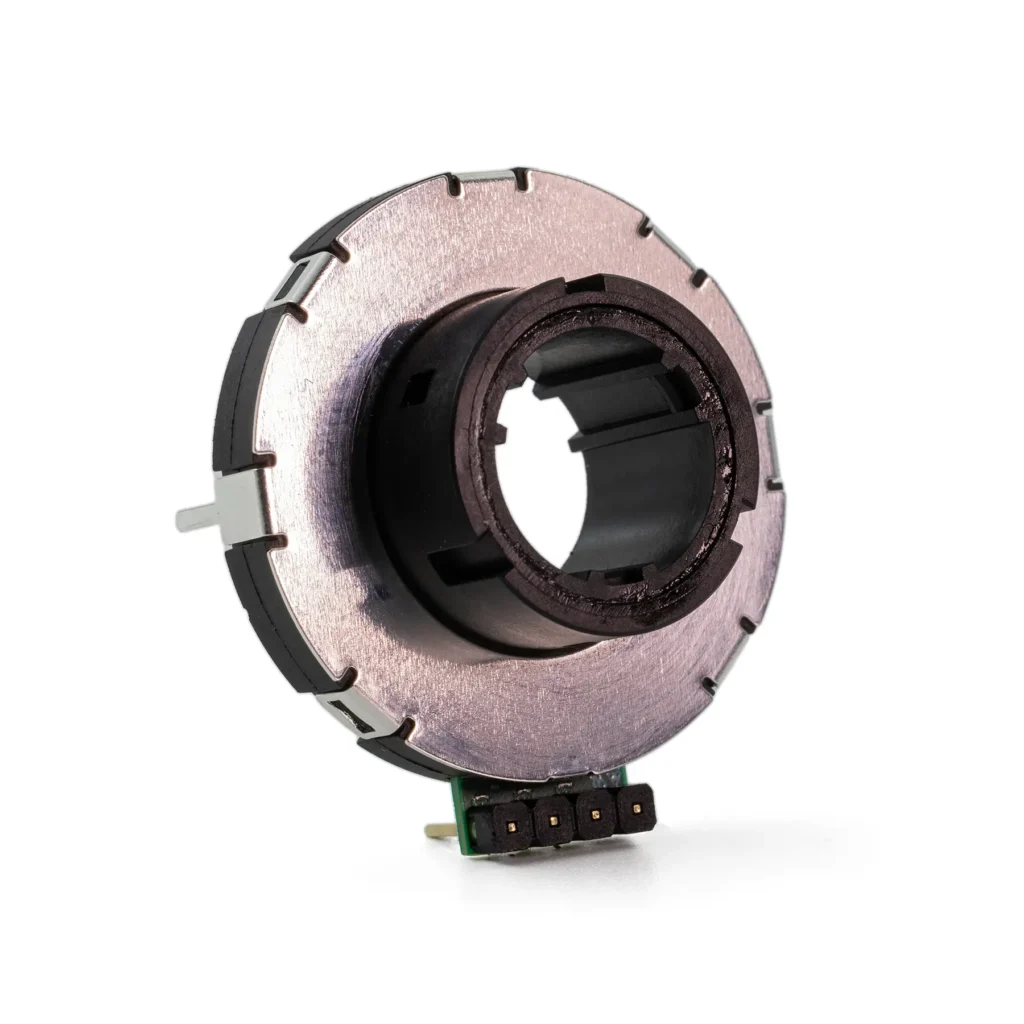

Because Grayhill starts with a strong quality management system, we can build a testing and validation program that is meaningful and consistent. The environmental, mechanical, electrical, and lifecycle tests we perform are built on traceable processes, controlled documentation, and consistent production.

A test result only matters when you can trust the inputs. Our certified quality system ensures that trust.