NASA’s Space Launch System rocket carrying the Orion spacecraft launches on the Artemis I flight test, Wednesday, Nov. 16, 2022.Photo Credit: (NASA/Joel Kowsky)

Vibration is one of the most common and demanding environmental stresses that electronic and electromechanical products encounter throughout their service life. Unlike mechanical shock, which introduces a single high intensity pulse, vibration applies continuous mechanical energy that accumulates over time and can lead to fatigue, wear, or intermittent electrical performance. Products used in vehicles, aircraft, industrial systems, construction equipment, and handheld devices must tolerate these stresses without degradation.

Grayhill performs vibration testing to confirm that mechanical structures, solder joints, connectors, and assemblies remain stable under controlled sinusoidal or random vibration. This testing provides the insight needed to ensure long term durability in real world environments.

Why Vibration Testing Matters in Engineering and Reliability Science

Vibration has been identified as a significant source of field failures in electronic systems across multiple industries. Studies published by NASA, IEEE, and IPC show that vibration induced fatigue affects solder joint reliability, connector performance, wire harness durability, and PCB structural behavior.

NASA researchers have demonstrated that random vibration accelerates crack initiation and propagation in solder joints and contributes to loosening and fatigue in mechanical fasteners. IEEE research documents that connector micro motion produces fretting corrosion, increases contact resistance, and causes intermittent electrical behavior. Additional IEEE studies show that vibration induced PCB flexure and cyclic strain lead to trace cracking and pad fatigue. IPC reliability studies further confirm that solder joints subjected to vibration experience earlier fatigue failure than those exposed only to thermal cycling.

Together, these findings show that vibration is not simply a mechanical concern but a multi-faceted reliability risk that must be evaluated during product development.

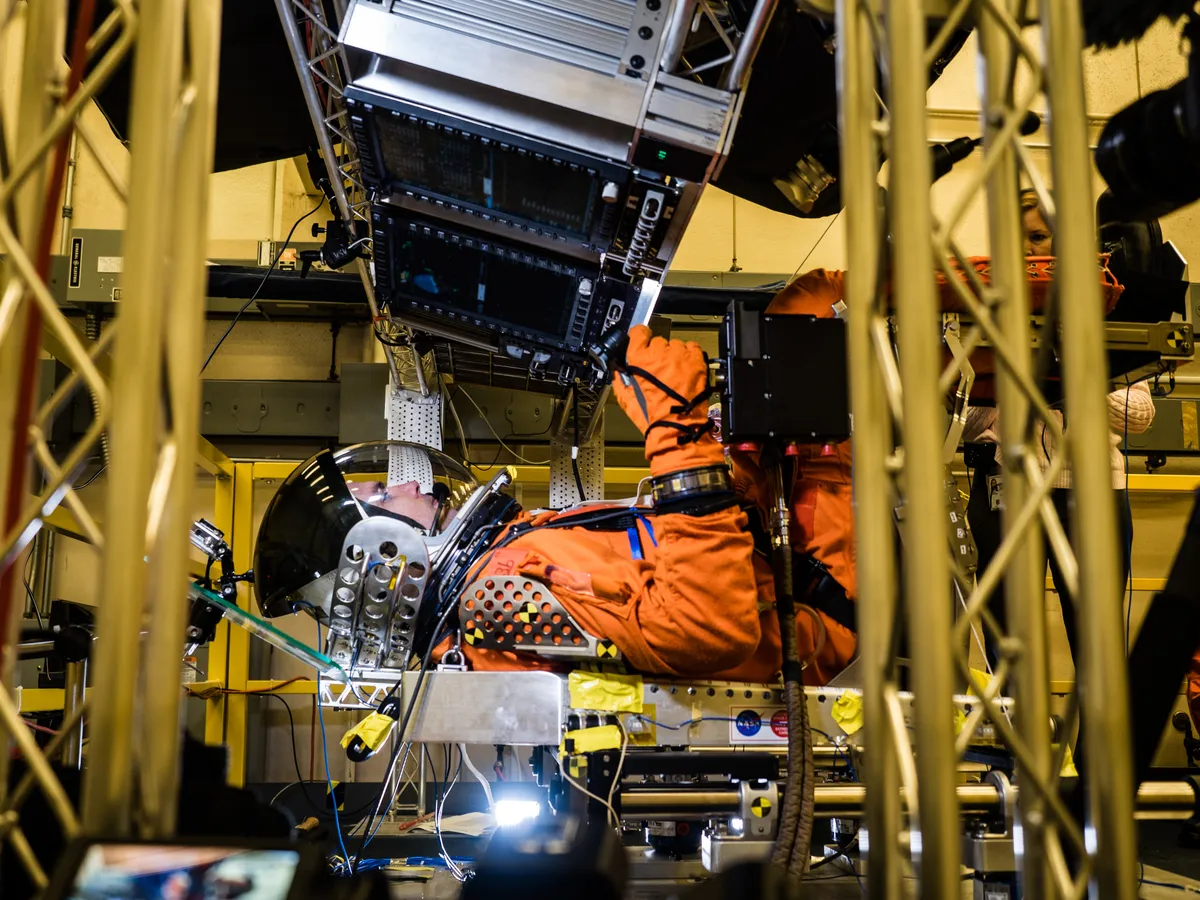

In the Rapid Prototyping Laboratory at NASA's Johnson Space Center in Houston, engineers simulate conditions that astronauts in spacesuits would experience when the Orion spacecraft is vibrating during launch atop the agency’s powerful Space Launch System rocket on its way to deep space. (Photo credit: NASA/Rad Sinyak)

Real Application Example: NASA’s Orion Spacecraft

NASA’s Orion spacecraft provides a clear example of how critical vibration testing is for mission success. During the Artemis I launch in 2022, Orion experienced intense acoustic and broadband random vibration as it rode the Space Launch System rocket into orbit. NASA performed extensive vibration testing on Orion flight hardware, avionics, and structural components to ensure stability during ascent, deep space operations, and atmospheric reentry². These tests evaluated solder joints, wiring harnesses, connectors, and mechanical structures under severe dynamic loading.

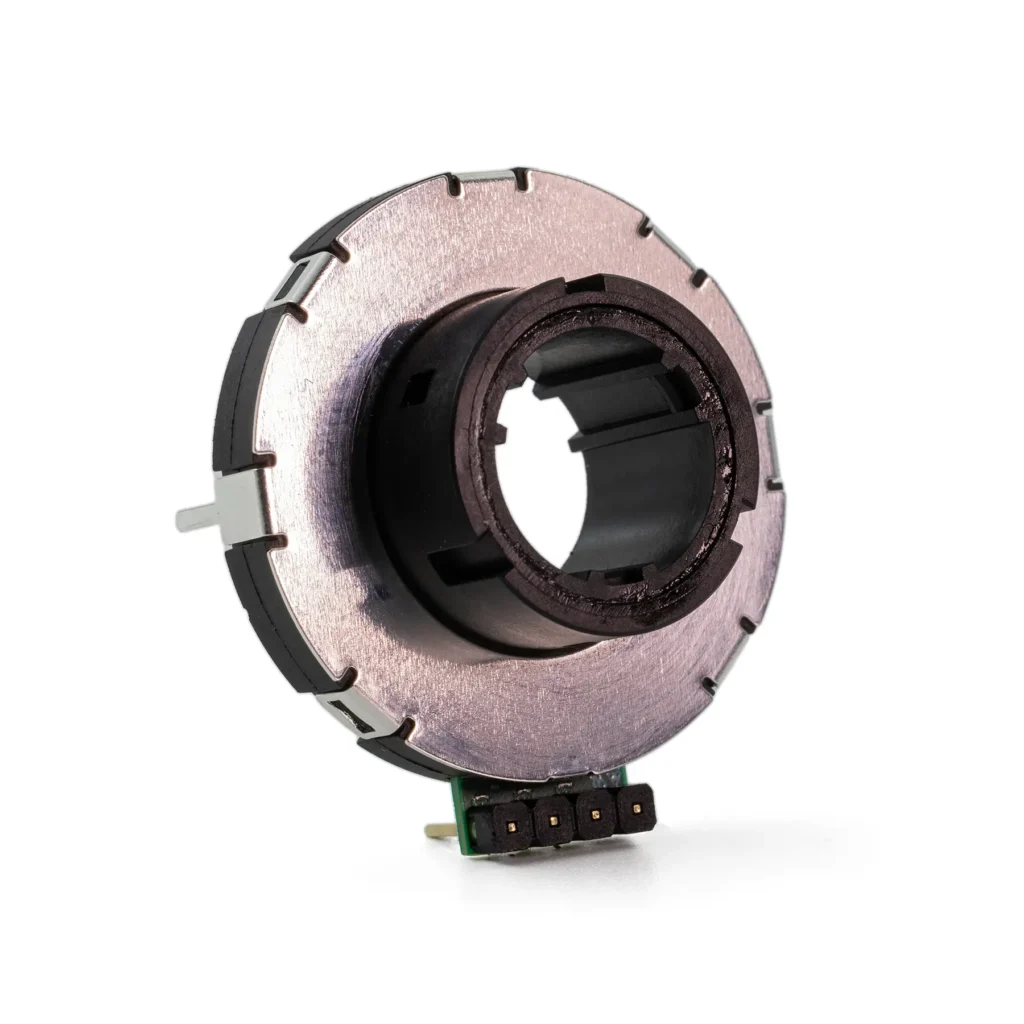

Grayhill’s 62AG Value Rotary Encoder met the stringent specifications required for this type of space application. By validating every component and subassembly through controlled vibration testing, Grayhill ensures that products such as the 62AG Value Rotary Encoder maintain performance in the harsh and unpredictable conditions encountered during missions like Artemis I. Orion’s successful flight demonstrates the importance of vibration qualification for equipment expected to operate in extreme environments.

(Photo credit: NASA/Robert Markowitz)

Failure Modes Revealed by Vibration

Vibration introduces stresses that can produce immediate or cumulative failure modes. Common issues include:

- Loosening of Fasteners

Fasteners can gradually lose preload due to micro motion, reducing structural rigidity and increasing wear. - Cracked Solder Joints

Cyclic strain accelerates solder fatigue, creating micro cracks that can grow until electrical discontinuity occurs. - Fretting Corrosion

Small amplitude, high frequency motion between mating contacts produces oxide debris and increased resistance. - Wire Fatigue

Repeated bending or flexing of conductors can cause copper strands to harden and fracture. - Connector Failures

Insufficient retention forces, poor interface geometry, or resonance can cause intermittent or permanent connection loss.

These mechanisms often cannot be detected through visual inspection alone, which is why controlled vibration testing is essential.

Standards That Shape Vibration Testing

Grayhill follows vibration test methods defined by leading industry standards. Each standard provides structured guidance for evaluating product behavior under vibration.

- MIL-STD-810, Method 514

Used widely in defense and aerospace. Defines operational vibration profiles including random, sine, and composite vibration. Emphasizes tailoring the environment to actual use conditions. - IEC 60068-2-6

Focuses on sinusoidal vibration for electronics and electromechanical components. Used to determine resonance frequencies and verify structural integrity. - ISO 16750-3

Relevant for automotive applications. Includes road induced vibration, engine vibration, and long duration fatigue conditions for vehicle mounted electronics.

These standards help ensure that vibration testing aligns with real world mounting conditions, loading profiles, and mission environments.

Understanding Sinusoidal and Random Vibration

- Sinusoidal Vibration

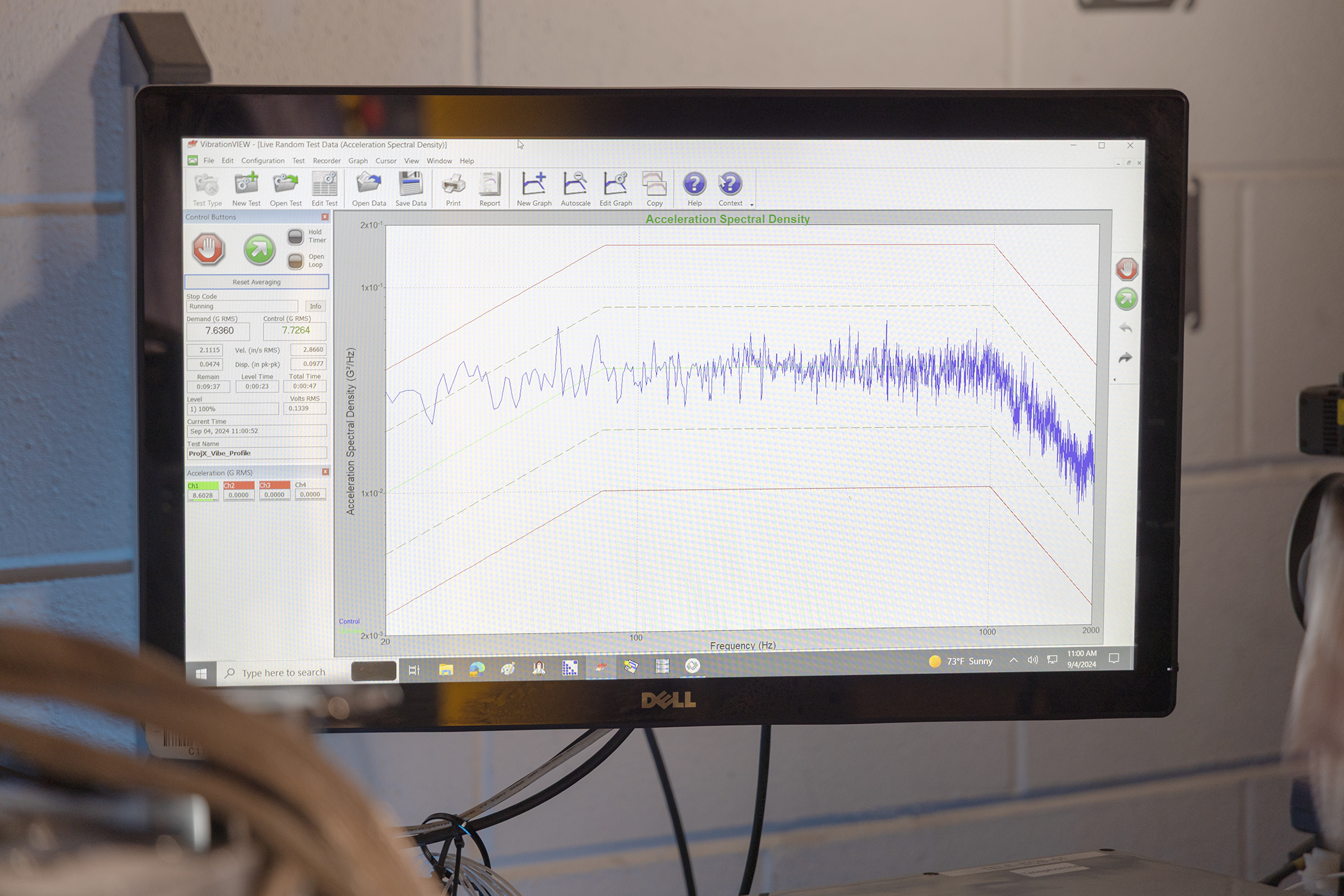

Sinusoidal vibration sweeps a single frequency across a defined range. It is ideal for identifying resonances where mechanical amplification occurs. Engineers use these results to locate structural weaknesses or mounting issues. - Random Vibration

Random vibration contains energy across a wide bandwidth and better represents actual operating environments such as vehicles or aircraft. Random profiles accelerate fatigue and reveal long term durability concerns more effectively than sinusoidal testing.

Both profiles are valuable and often used together to provide a complete reliability assessment.

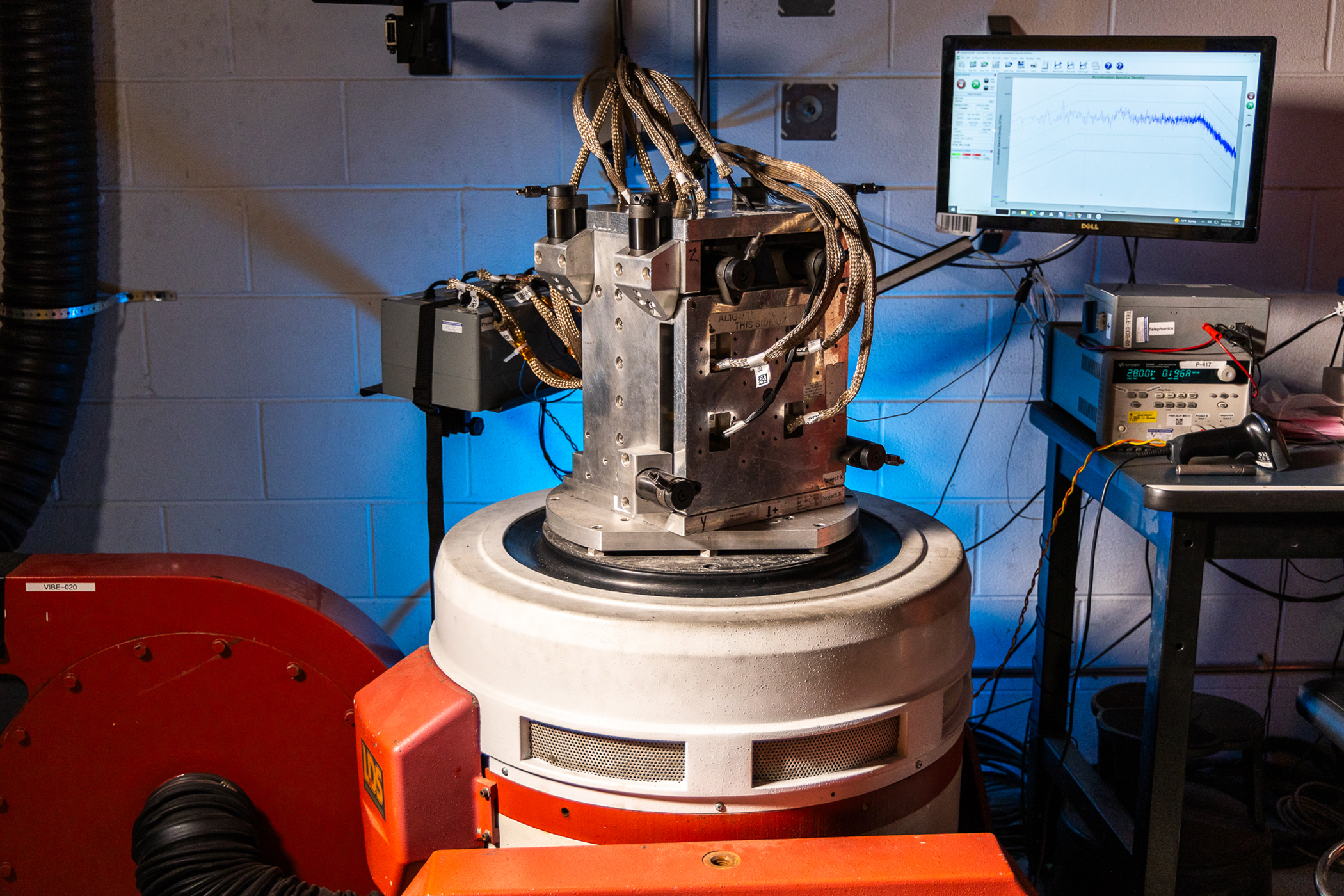

How Grayhill Performs Vibration Testing

Grayhill uses electrodynamic shakers capable of generating precise, repeatable vibration profiles based on customer requirements and industry standards. The testing process includes:

- Representative Mounting

Products are mounted using hardware or fixtures that simulate actual installation to ensure realistic stress distribution. - Multi Axis Testing

Vibration is applied along the X, Y, and Z axes to capture direction dependent behavior. - Functional Monitoring During Vibration

Electrical continuity, actuation performance, output stability, and tactile behavior can be monitored in real time to detect intermittent issues that may not appear after the test ends. - Post Test Inspection and Validation

After testing, components undergo structural inspection, solder joint evaluation, connector retention checks, electrical testing, and visual examination to confirm reliability.

How Vibration Data Improves Product Design

Vibration testing provides actionable engineering insight that helps:

- Reinforce PCB mounting and structural ribs

- Improve wire routing and strain relief

- Select connectors with higher retention forces

- Enhance solder joint reliability

- Optimize enclosure design and material selection

- Avoid frequency bands where resonance amplifies mechanical stress

This data helps Grayhill improve durability, reduce field failures, and refine product robustness across all environmental conditions.

Customer Advantages

Vibration tested products offer several key benefits:

- Stronger solder joint integrity

- Greater confidence in connector stability

- Increased resistance to fatigue related failures

- Fewer intermittent electrical issues

- Enhanced durability in harsh or high vibration applications

- Improved overall long-term reliability

For customers in aerospace, defense, industrial, and automotive environments, these benefits are essential for mission success and operational safety.