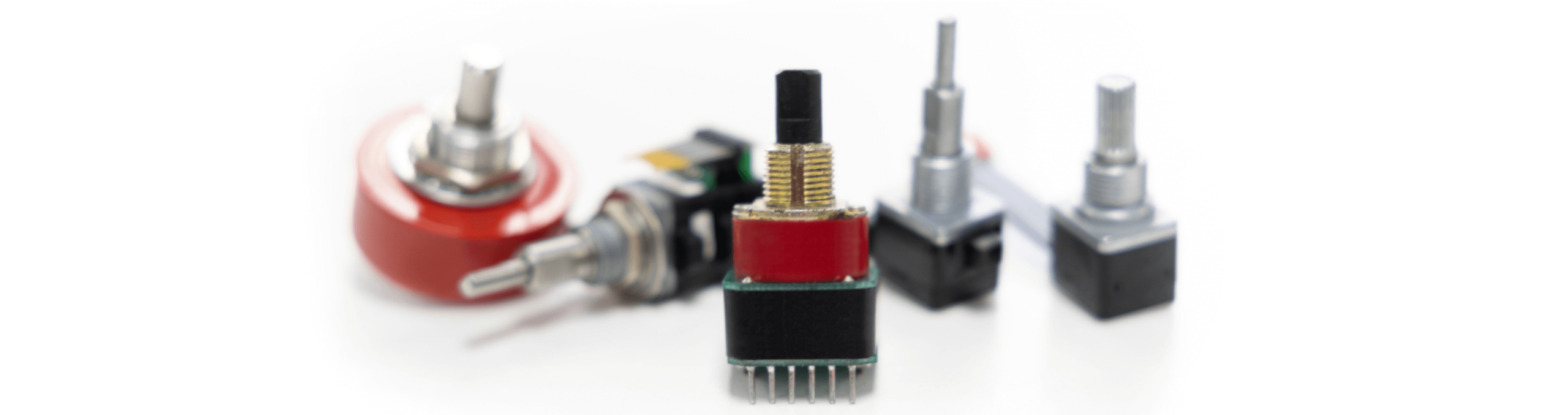

ENERGY-SAVING HAPTIC ENCODERS BUILT FOR EXTREME DURABILITY

100x LONGER LIFE THAN COMPETITORS

Easy on Battery Power, Tough in Harsh Environments

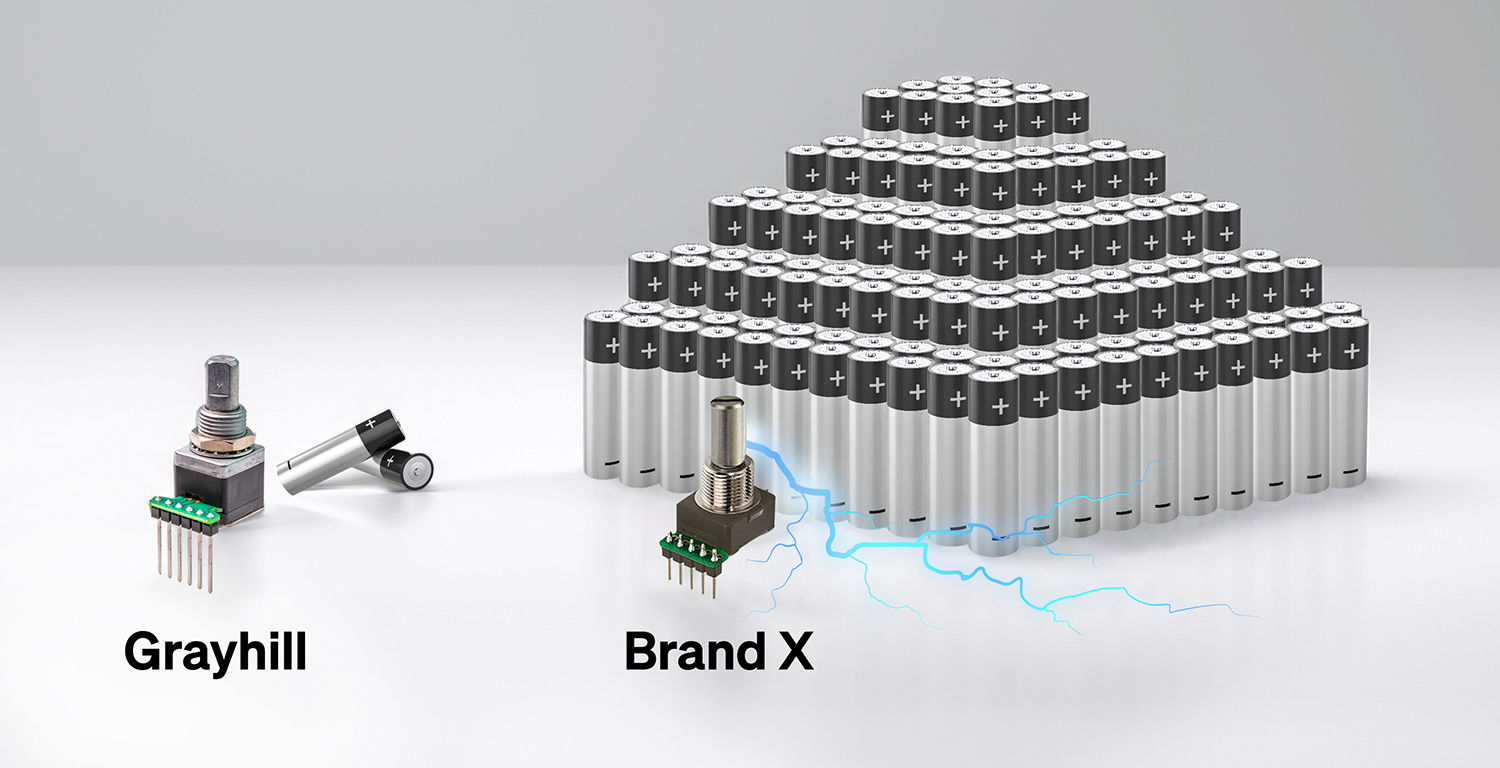

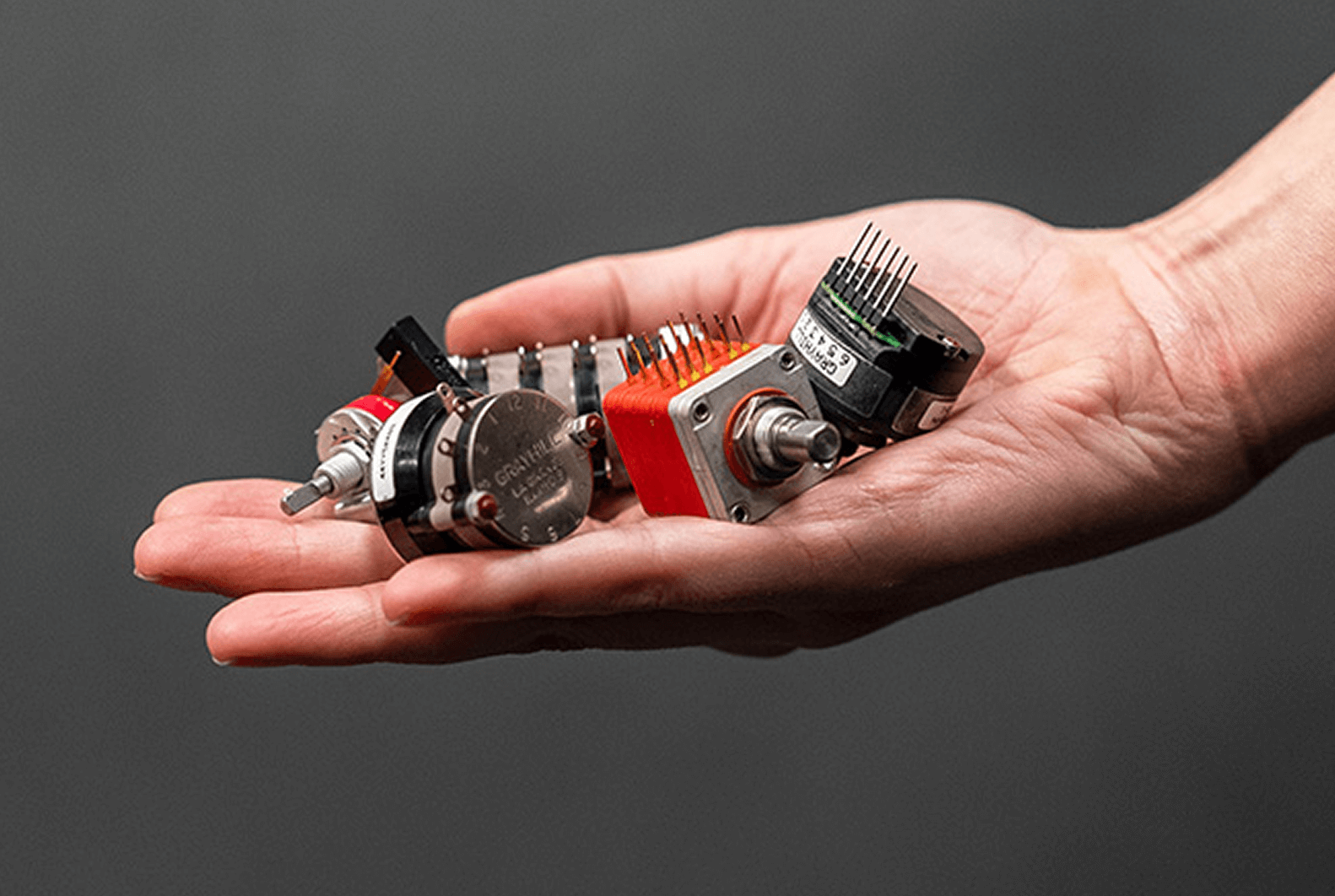

Grayhill encoders boast 100 times more battery life than competing models. For manufacturers looking for low-power, high-performance encoders for their knobs, switches, pushbutton controls, or joysticks, Grayhill’s Premium Haptic Rotary Encoders are the benchmark by which all others are measured.

REQUEST YOUR FREE SAMPLES

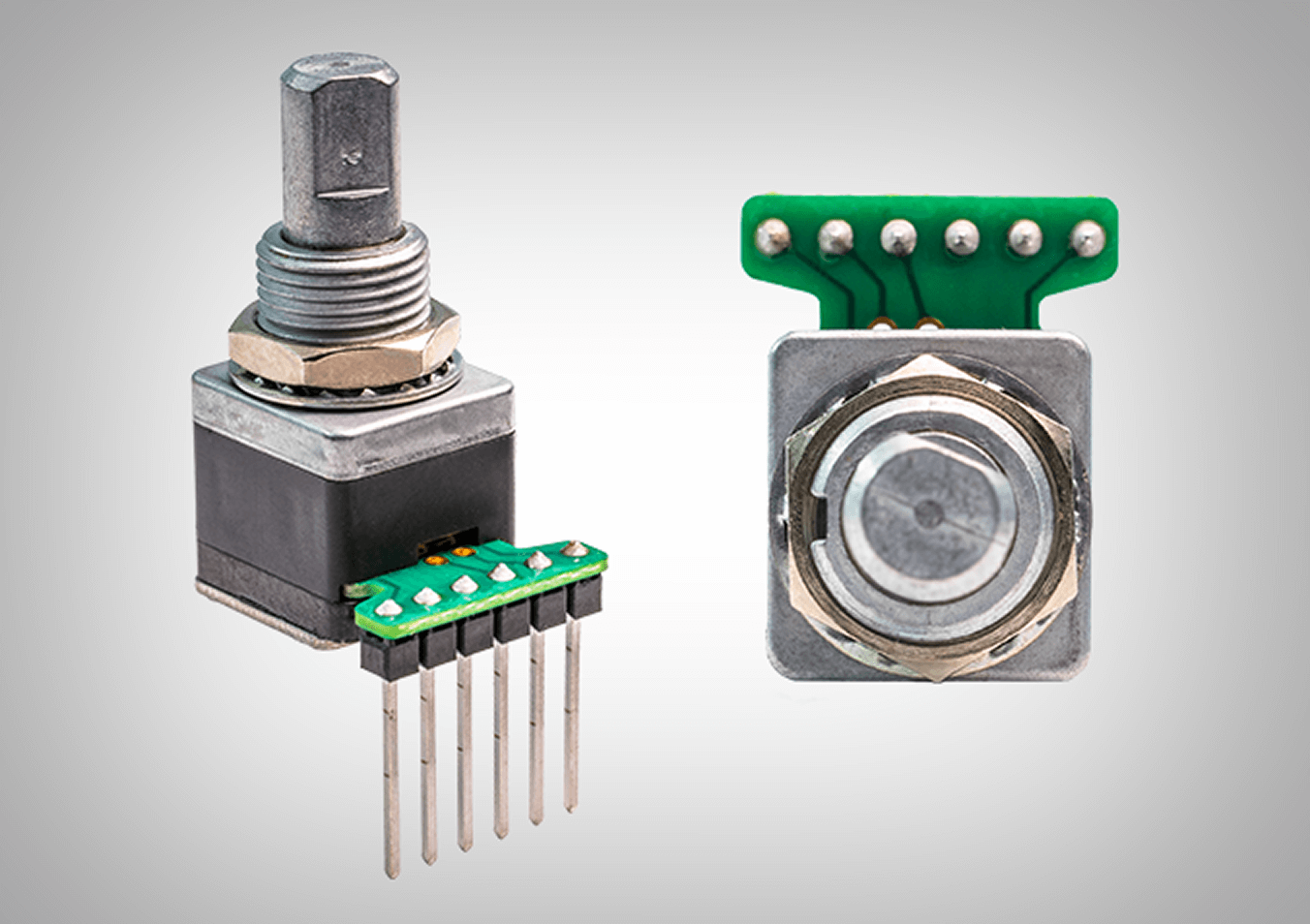

62AL22-02-020C: Coarse resolution, best for quick navigation

62AL15-02-020C: Medium resolution, best for general purpose use

62AL11-02-020C: Fine resolution, best for precision adjustments

Samples are in high demand, so click below to request your free sample now:

A FULL 2 YEARS OF POWER ON 2 AA BATTERIES

Our encoders boast 100 times more battery life than competing models for significant long-term savings on maintenance and replacement costs.

DELIVER THE PERFECT BLEND OF FEEL AND FUNCTION

With every turn or press, our Premium Haptic Rotary Encoders make users feel like they are intuitively connected to the machine they are operating. They are also built to conserve energy and withstand harsh environments—two critical advantages for manufacturers looking for flexibility and reliability in their next control panel assembly.

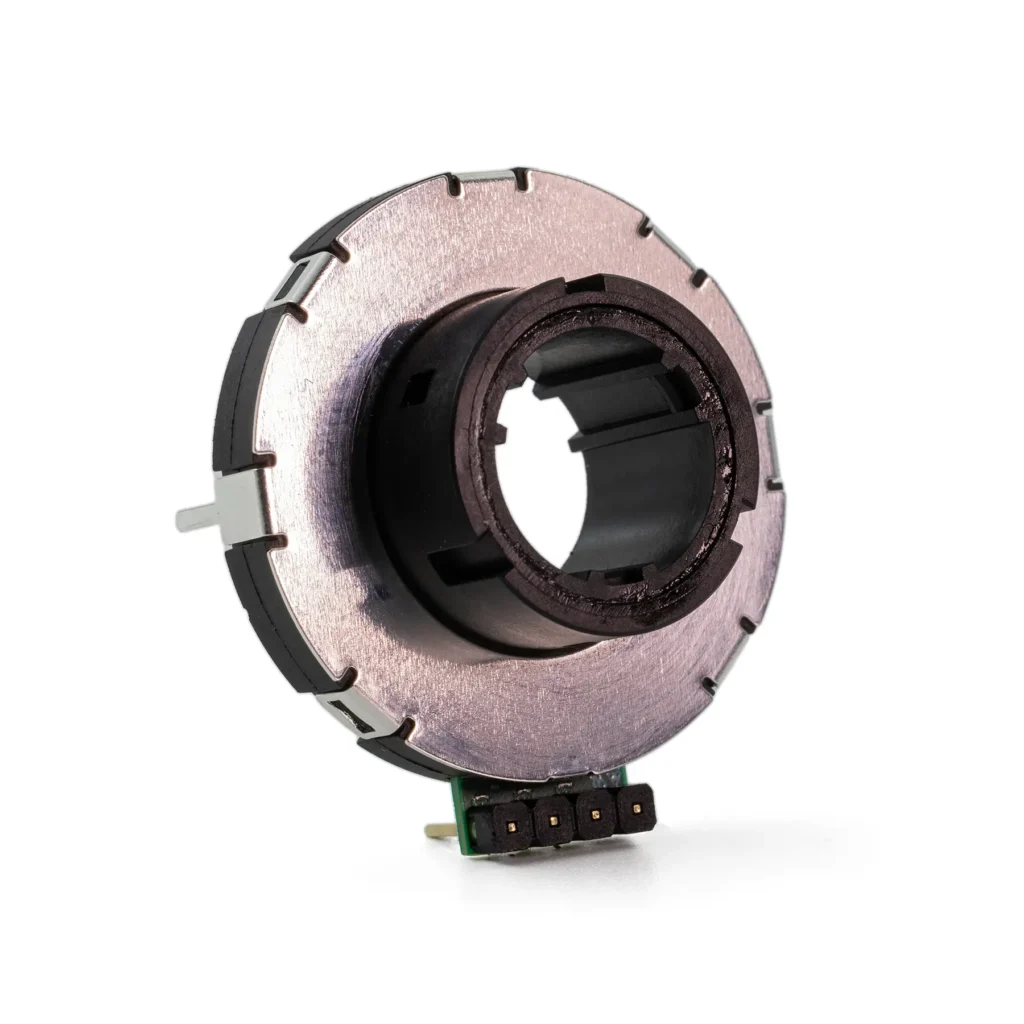

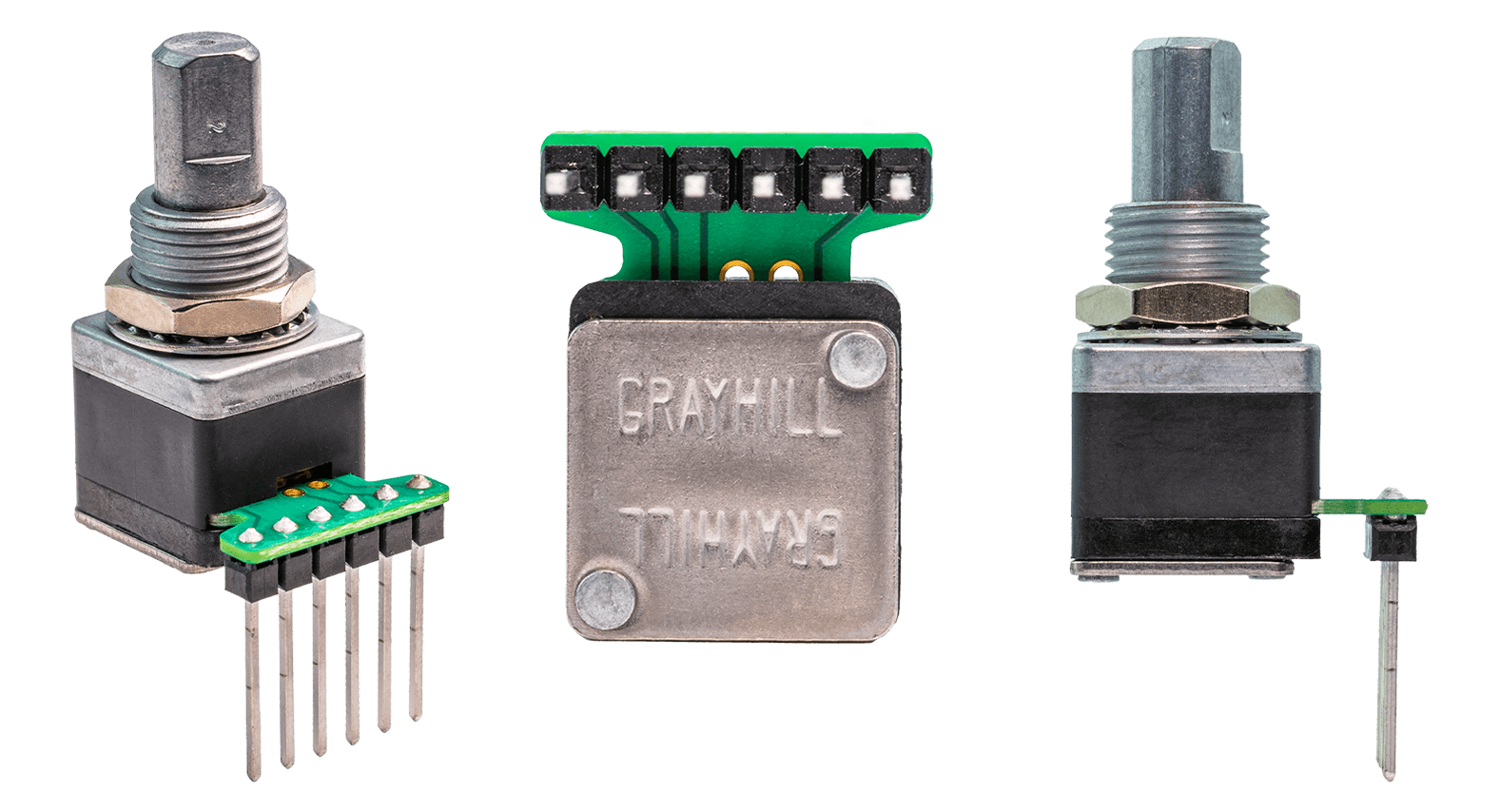

62A-D-V PREMIUM HAPTIC ENCODER

With rugged durability and premium tactile feedback with up to 32 detent and non-detent positions, Grayhill’s 62A-D-V delivers a powerful trifecta of benefits for manufacturers:

- Premium Tactile Control: Offers a superior haptic feel with customizable torque (like the high-torque style D), ensuring a precise and confident user interface.

- Rugged Durability: Engineered to perform in harsh conditions, withstanding extreme temperatures from -40 °F to 185 °F [-40 °C to 85 °C], significant vibration (15G), and mechanical shock (100G).

- Energy-Efficient Design: Our 62V encoder features low power consumption (as low as 3.3 V), perfect for high-efficiency components like CPUs and microcontrollers and battery-powered devices.

COMMON APPLICATIONS

- Healthcare

- INDUSTRIAL

- Automotive & Off-Highway

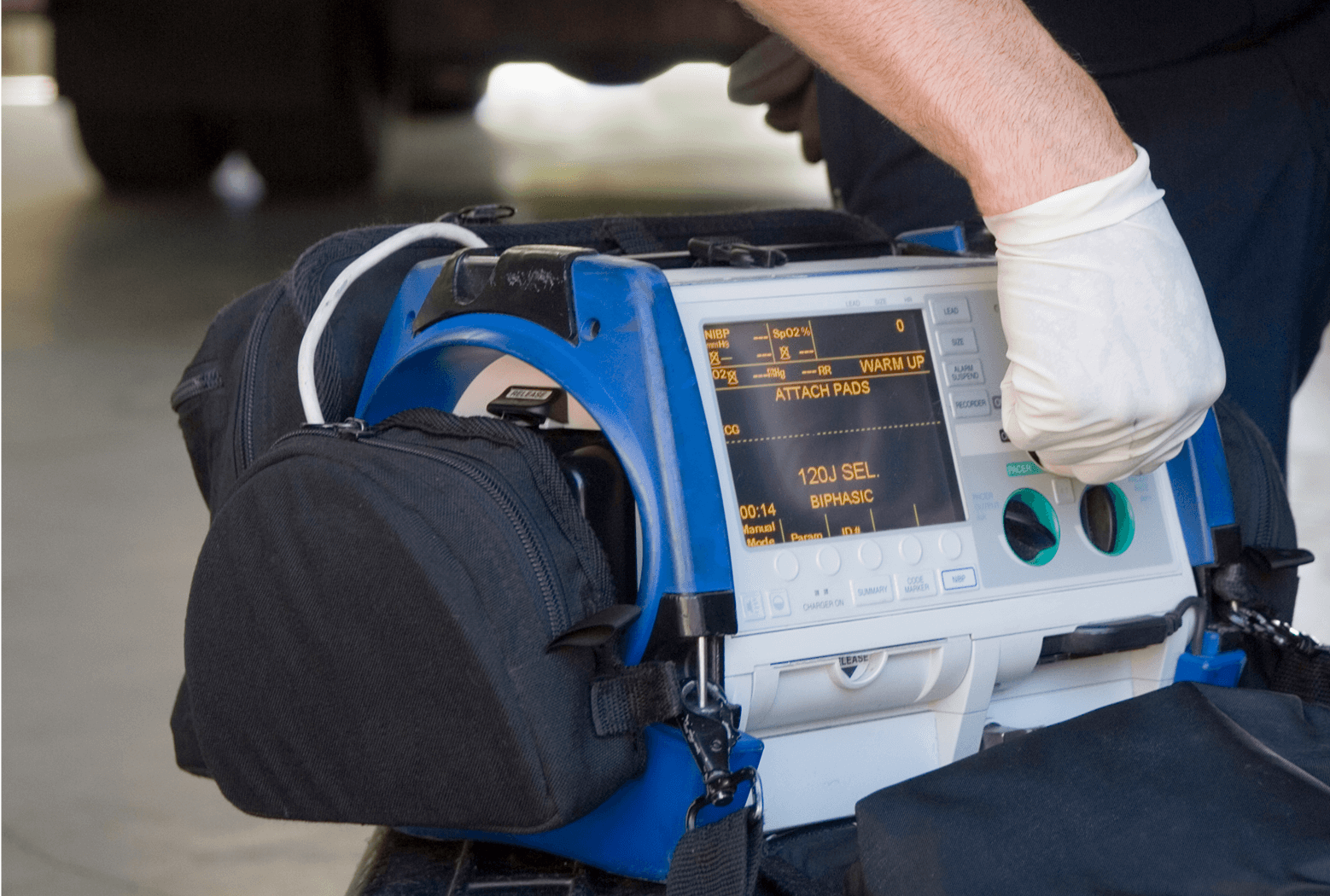

Healthcare

For medical device OEMs and mobile healthcare applications such as ultrasounds, portable monitor devices, ambulances and healthcare transport, user preference is key to gaining market share. Integrating our low-power haptic encoders helps you create portable battery-powered products with a superior, intuitive interface. This gives healthcare professionals the confidence and precise control they need, making your device the trusted choice in the field.

INDUSTRIAL

We give OEMs the design flexibility to build better industrial controls. Our encoders provide durability to minimize downtime and consistent haptics for an intuitive experience. With low-power options, you can create a long-lasting product that your customers will love to use.

Automotive & Off-Highway

Enhance the in-cabin experience for your GPS and Driver Information Systems. Grayhill’s encoders provide your customers premium haptic feedback that creates a high-quality, luxury feel combined with a rugged design that ensures long-term reliability in harsh environments.

GET 1 MILLION+ CYCLES: PERFORMANCE THAT COMPETITORS CAN’T TOUCH

Grayhill’s Premium Haptic Rotary Encoders deliver 10-66 times more turns than competitors, lasting years longer and lowering your total cost of ownership.

THE DIFFERENCE IS IN THE DETAILS

- Optical Coupling Technology

- Optional O-Ring Sealing

- Customizable Features

Optical Coupling Technology

We don’t just build encoders. We engineer them for a superior feel and a longer life. The secret behind our encoders’ durability is in our optical coupling technology, which is non-contacting for less wear and tear.

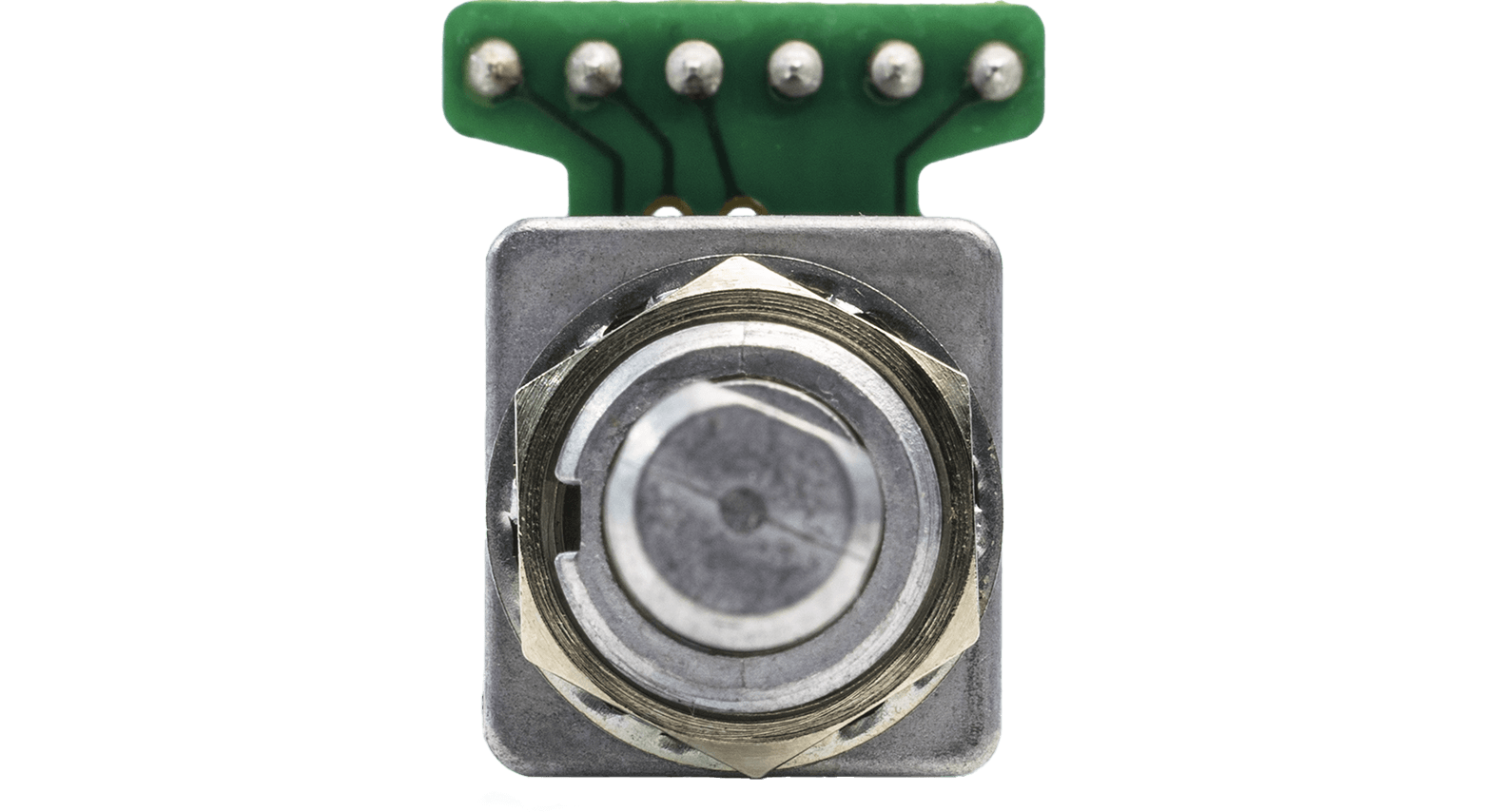

Optional O-Ring Sealing

We’ve added an O-ring on the shaft and a panel seal to the top surface, ensuring that water, dust, and foreign debris can’t get in. Our IP67-rated encoders undergo rigorous in-house testing, including vibration, shock, and temperature extremes, ensuring they perform reliably in the field.

Customizable Features

We can work with you to customize the torque profile, detent feel, and button actuation force to get the exact haptics you want. It’s all part of our commitment to creating high-quality, intuitive interfaces that help you sell more machines.

Key Features

Long Rotational Life: Our Premium Haptic Rotary Encoders are designed to last for years, utilizing non-contacting technology with a minimum rating of 1 million turns.

Premium Haptic Feedback: Deliver a premium haptic feel that stays consistent over time or customize to fine-tune the “click” and resistance to your preference.

Environmental Durability: Our sealed-option encoders keep dust and water out and withstand mechanical vibration and shock.

Optional Pushbutton: Combine two functions – rotation and selection – into a turn-to-navigate, press-to-select user interface.

Low-Power Consumption: Designed for energy-efficient systems, the 62V series operates at 3.3 V to minimize power usage in your application.

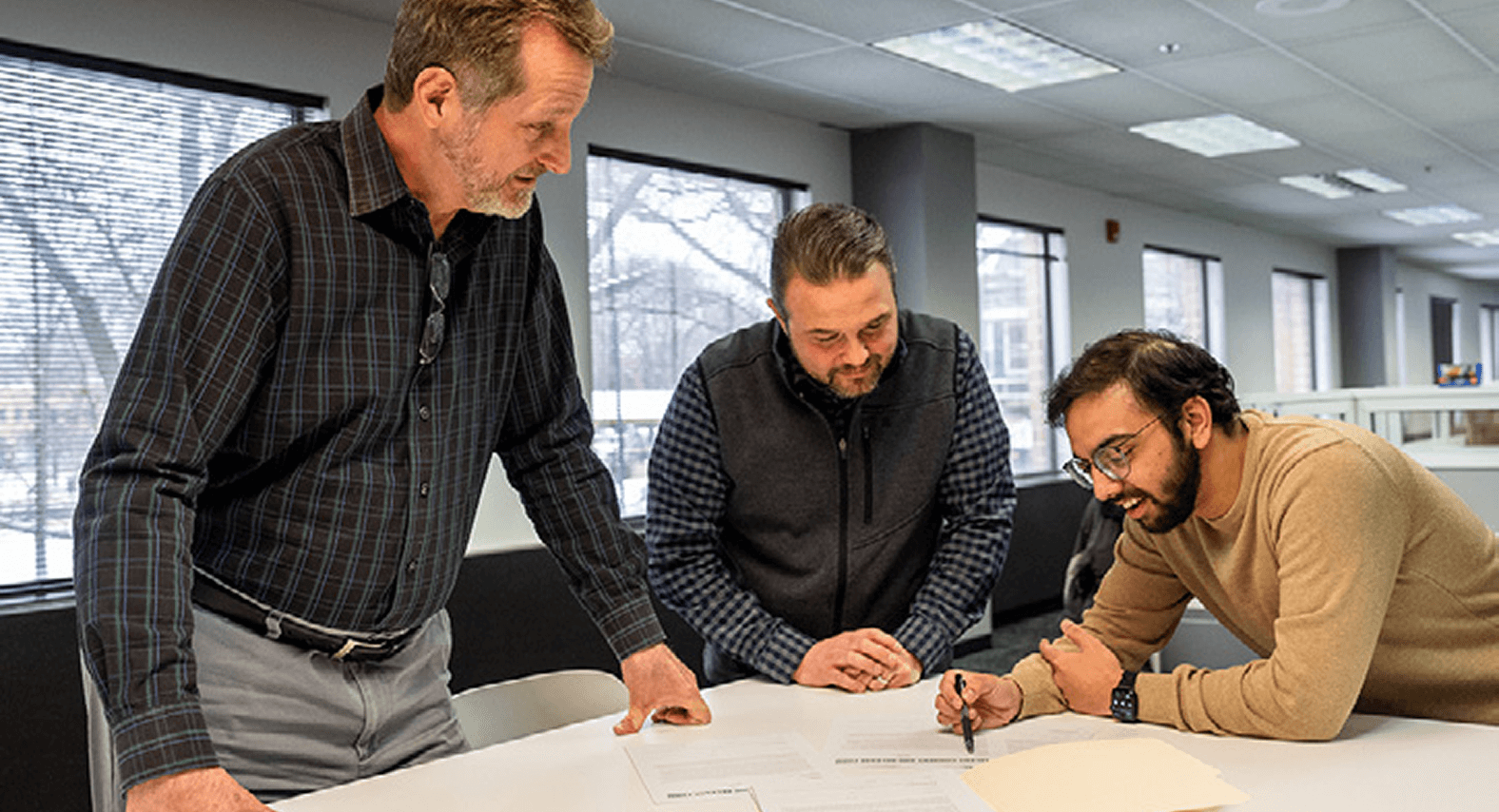

BACKED BY 80+ YEARS OF MANUFACTURING EXPERTISE

At Grayhill, we’re more than just an OEM component supplier. We have a legacy of innovation spanning 80+ years and a team of over 125 experienced engineers who are experts in everything from design and ergonomics to software and reliability. Our vertical integration—from molding to tooling and testing—allows us to control every part of the process and bring custom products to market faster.

NOT SEEING WHAT YOU’RE LOOKING FOR?

Where Others Limit, Grayhill Expands

Our products outperform because of our thoughtful quality process.

STAY UP TO DATE WITH OUR BLOG

Learn more about Grayhill and our extensive range of products and services.